Electric Choke Guide Wiring: Master The Connections For Optimal Engine Performance

An electric choke guide is a crucial component in a vehicle’s intake system, regulating airflow to the engine. Electric chokes use heat to open the choke valve, which is controlled by a wiring system that provides power and ground connections. The choke guide governs the movement of the choke valve, ensuring proper airflow during engine startup and warm-up phases. Understanding the wiring process is essential for optimal engine performance, as it connects the choke guide to the power and ground sources. Related concepts, such as the choke valve, carburetor, spring, and coil, play vital roles in the choke guide system. By wiring the electric choke guide correctly, the engine can efficiently receive the necessary airflow for smooth operation.

What is an Electric Choke Guide?

In the realm of internal combustion engines, the electric choke guide plays a pivotal role in orchestrating airflow regulation. This unassuming device governs the correct mixture of fuel and air, ensuring optimal engine performance, particularly during cold starts. It operates alongside the carburetor, a crucial component responsible for metering fuel before it enters the cylinders.

An electric choke guide is essentially a solenoid valve actuated by electricity. It consists of two key components: a choke valve and a coil. When the engine is cold, the choke valve remains partially closed, restricting airflow into the carburetor. This enriches the fuel-air mixture, providing the necessary boost for a smooth ignition. As the engine warms up, an electric current flows through the coil, generating heat that expands a spring. This mechanical action disengages the choke valve, allowing more air into the carburetor and creating the ideal fuel-air ratio for optimal engine operation.

Understanding the intricacies of the electric choke guide and its related concepts empowers you to tackle any potential issues with efficiency and precision. By delving into the mechanics of this vital component, you not only enhance your understanding of engine systems but also gain the confidence to maintain your vehicle’s smooth performance for years to come.

Understanding Electric Chokes: The Engine’s Warm-Up Assistant

When the weather turns chilly, starting your car can become a bit of a challenge. But don’t fret, electric chokes have emerged as valiant allies in this battle. These clever devices aid in regulating airflow within the engine, ensuring a seamless startup even in the most frigid conditions.

Electric chokes achieve their magic by utilizing the power of heat. As you turn the ignition key, electrical current flows through a coil inside the choke assembly. This current generates heat, causing a bi-metallic spring to expand. This expansion, in turn, forces open the choke valve, allowing more air and fuel into the engine.

As the engine warms up, the bi-metallic spring contracts, gradually closing the choke valve and reducing the amount of fuel entering the engine. This delicate balance prevents flooding, ensures smooth idling, and optimizes fuel efficiency.

The Importance of Wiring in Electric Choke Guides

The electric choke guide is a crucial component in ensuring optimal airflow regulation for your vehicle’s engine. Proper wiring is essential for the choke guide to function effectively and maintain a smooth running engine.

Types of Wiring Connections

There are two main types of wiring connections used in electric choke guides: *terminal connections* and *spliced connections*. Terminal connections involve attaching wires to designated terminals on the choke guide. These terminals have specific functions and should not be interchanged. Spliced connections, on the other hand, involve connecting wires by physically joining them together and protecting the junction with insulation.

Importance of Correct Wiring

Incorrect wiring can lead to a variety of issues with your vehicle’s performance. It can result in the choke valve not opening or closing properly, causing engine idling problems and fuel inefficiency. Moreover, a poorly wired choke guide may pose a safety hazard, potentially leading to engine fires or other malfunctions.

Cautions for Wiring

When wiring an electric choke guide, it is essential to take precautions to ensure the safety and reliability of the connection. Use the correct wire gauge specified for the choke guide and secure all connections with electrical tape or crimp connectors. Avoid using soldered connections, as they can become brittle over time and create weak points in the wiring.

Proper wiring of the electric choke guide is paramount for its functionality and the overall performance of your vehicle. By understanding the importance of wiring and utilizing the correct techniques, you can ensure that your engine operates smoothly and efficiently for years to come.

Function of a Choke Guide

An electric choke guide is a crucial component of your car’s carburetor system, working in harmony to ensure a smooth and efficient engine operation. The choke guide’s primary job is to control the movement of the choke valve, which in turn regulates the airflow into the engine.

The Mechanics of a Choke Guide

When the engine is cold, the choke valve is partially closed, restricting the airflow into the engine. This is necessary to create a richer air-fuel mixture, which is easier to ignite when the engine is cold. The choke guide, through its connection to an electric circuit, heats up a coil, which expands and pushes against the choke valve, opening it gradually as the engine warms up.

Regulating Choke Valve Movement

The choke guide’s role is to govern the movement of the choke valve in response to changing engine temperatures. When the engine is cold, the choke guide keeps the choke valve partially closed, restricting airflow. As the engine warms up, the electric current in the coil increases, generating more heat and causing the choke guide to open the choke valve further. This allows more airflow into the engine, resulting in a leaner air-fuel mixture.

Optimal Engine Performance

The proper functioning of the choke guide is essential for optimal engine performance. An incorrectly adjusted or faulty choke guide can lead to problems such as hard starting, rough idling, and poor fuel economy. By controlling the choke valve’s movement precisely, the choke guide ensures that the engine receives the correct air-fuel mixture at different temperatures, contributing to smooth running and efficient combustion.

The Intake System: A Vital Connection to the Electric Choke Guide

Introduction:

The intake system plays a crucial role in the overall functioning of any engine. Specifically, it’s directly connected to the electric choke guide, a component that ensures optimal airflow for efficient engine performance. Understanding this connection is essential for understanding the operations of your engine.

Role of the Intake System:

The intake system is responsible for drawing air into the engine. It’s composed of several components, such as the air filter, intake manifold, and throttle body. The air filter cleans the incoming air before it enters the engine to prevent dirt and debris from damaging internal components. The intake manifold distributes the filtered air to each cylinder. Finally, the throttle body regulates the airflow into the engine, adjusting the amount of air supplied based on engine demand.

Connection to the Electric Choke Guide:

The electric choke guide is closely connected to the intake system. When the engine is cold, the choke valve is closed to restrict airflow, creating a richer air-fuel mixture. This helps the engine start and run smoothly until it warms up. The electric choke guide is responsible for regulating the movement of the choke valve. When the engine starts, the electric choke guide gradually opens the choke valve by applying heat to a spring that controls its position. As the engine warms up, the choke valve opens completely, allowing for proper airflow.

Conclusion:

The intake system is an essential component of the engine, directly connected to the electric choke guide. Understanding the connection between these two components provides insights into the engine’s airflow regulation and how it contributes to efficient engine performance.

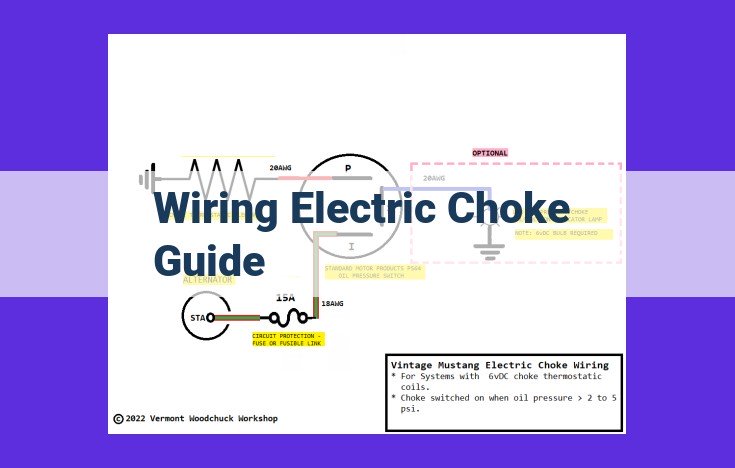

Wiring the Electric Choke Guide

In the world of automotive mechanics, understanding the intricacies of an electric choke guide is essential for guaranteeing optimal engine performance. When venturing into the realm of wiring this vital component, a clear understanding of the underlying principles and proper techniques is paramount.

To begin, let’s establish a firm grasp on the electrical connections that power the electric choke guide. Typically, these devices feature two terminals: one for power and one for ground. The power terminal, as its name suggests, provides electricity to the choke guide, allowing it to generate the necessary heat to open the choke valve. On the other end of the spectrum, the ground terminal serves as a crucial path for the completion of the electrical circuit, ensuring a seamless flow of electricity.

When embarking on the task of wiring an electric choke guide, accuracy and precision are of utmost importance. Start by identifying the power and ground terminals on the choke guide, usually marked with distinct labels or color coding. Next, connect the power terminal to a power source, such as the vehicle’s ignition switch or battery. This connection will provide the necessary voltage to activate the choke guide.

For the ground terminal, establish a secure connection to a ground point on the vehicle’s chassis or engine block. This connection ensures the completion of the electrical circuit, allowing current to flow freely and activate the choke guide.

As you navigate the wiring process, take extra care to insulate all connections thoroughly. Electrical tape or heat shrink tubing are excellent choices for providing insulation, preventing short circuits, and ensuring the longevity of the electrical system.

Finally, once the wiring is complete, double-check all connections to verify their tightness and proper functionality. A faulty connection can hinder the proper operation of the electric choke guide, potentially leading to engine performance issues.

By adhering to these guidelines and exercising meticulous attention to detail, you can successfully wire an electric choke guide, ensuring its efficient operation and optimal engine performance.

Related Concepts

To gain a comprehensive understanding of electric choke guides, it’s crucial to delve into the essential components and their functions within the engine system.

Choke Valve

The choke valve is a crucial component of the electric choke guide mechanism. Its primary role is to restrict airflow entering the engine during cold starts. By partially blocking the air intake, the choke valve creates a richer fuel mixture, which is necessary for efficient combustion when the engine is cold.

Carburetor

The carburetor plays a vital role in the operation of the electric choke guide. It mixes fuel and air in a precise ratio, ensuring optimal engine performance. The electric choke guide is directly connected to the carburetor and controls the choke valve’s position based on engine temperature.

Spring

An integral part of the electric choke guide is the spring. This component is responsible for closing the choke valve when the engine warms up. As the engine temperature rises, the electric choke unit receives power, which generates heat and expands a small coil. This expansion exerts force on the choke valve, overcoming the force of the spring and allowing more air to flow into the engine.

Coil

The coil is the heart of the electric choke system. Its primary function is to generate heat when the engine is cold. The flow of electricity through the coil causes it to expand, which in turn opens the choke valve to increase airflow. As the engine temperature rises, the coil cools down and contracts, allowing the spring to close the choke valve.

By understanding the interconnected roles of these components, it becomes clear how the electric choke guide effectively regulates airflow and optimizes engine performance in varying operating conditions.