Troubleshooting Carburetor Float Issues: Optimizing Fuel Regulation For Enhanced Performance

To troubleshoot carburetor float issues, check the float level, which regulates fuel flow. The float needle valve and seat must seal properly to prevent fuel leakage. The float tang adjusts the level, and a worn or damaged fuel inlet seat can cause leaks. Common problems include worn components and debris. Measure and adjust the float level using specific instructions for the carburetor model. Incorrect float level can lead to fuel starvation or flooding. Advanced troubleshooting techniques may be needed for complex issues. Maintaining the correct float level is crucial for optimal carburetor performance.

Understanding the Significance of Float Level for Optimal Carburetor Performance

Imagine the float level in your carburetor as a tiny guardian, constantly monitoring the fuel flow to ensure your engine runs smoothly. Much like the water level in a toilet, the float level maintains a precise fuel level in the carburetor’s float bowl. This delicate balance ensures an adequate supply of fuel while preventing overflow.

A well-adjusted float level is crucial for several reasons. First, it prevents fuel starvation, which can lead to engine hesitation or stalling. An excessively low float level may not allow enough fuel into the bowl, depriving the engine of the lifeblood it needs. Conversely, a float level set too high can cause flooding, where excess fuel enters the engine, causing it to stumble or even stall.

Furthermore, a stable float level safeguards against lean or rich running conditions. A lean mixture, resulting from a low float level, reduces engine power and fuel efficiency, while a rich mixture, caused by a high float level, can foul spark plugs and increase emissions.

Troubleshooting Float Level Issues

Like any diligent guardian, the float level may occasionally encounter challenges. If you suspect a float level issue, here are a few common culprits to check:

-

Sticking float needle: The float needle valve regulates fuel flow into the float bowl. If it gets stuck or worn, it can prevent the fuel level from being maintained.

-

Worn float needle seat: The float needle valve mates with a seat inside the carburetor. Over time, this seat can become worn or damaged, allowing fuel to leak.

-

Bent float tang: The float tang is a small, adjustable tab that influences the float’s position. A bent tang can throw off the float level setting.

Maintaining an optimal float level is essential for carburetor health and engine performance. By understanding its significance and troubleshooting potential issues, you empower yourself to keep your carburetor running at its best, ensuring a smooth and efficient ride.

The Float Needle Valve: The Fuel Flow Regulator of Your Carburetor

Every engine relies on a steady supply of fuel to perform at its best. In a carburetor, the float needle valve plays a crucial role in regulating this fuel flow, ensuring that the engine receives the correct amount of fuel for optimal performance.

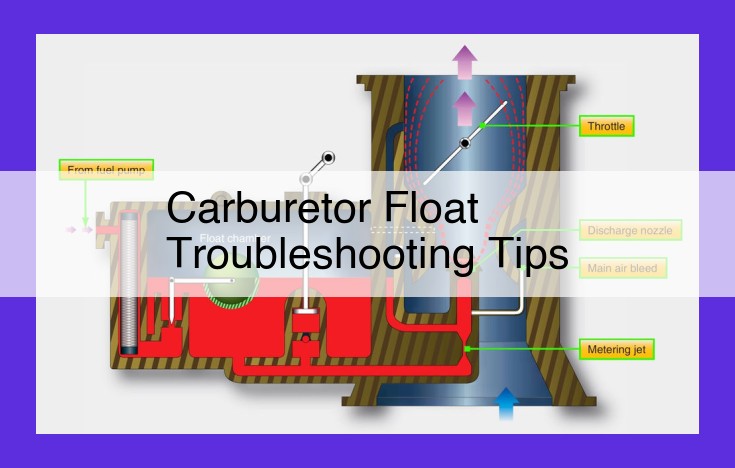

The float needle valve is located within the carburetor’s float bowl, which acts as a reservoir for the fuel. As fuel flows into the bowl, a float rises or falls, depending on the fuel level. This float is connected to the needle valve, which opens or closes to control the flow of fuel into the bowl.

When the fuel level in the bowl drops, the float also drops, which in turn opens the needle valve. This allows more fuel to enter the bowl, raising the float and closing the needle valve once the desired fuel level is reached. This process creates a feedback loop that maintains a consistent fuel level within the carburetor.

A properly functioning float needle valve is essential for several reasons. First, it prevents fuel starvation, which can occur if the fuel level in the bowl is too low. Fuel starvation can cause engine performance issues such as hesitation, stalling, and reduced power. Second, it prevents flooding, which can happen when the fuel level in the bowl is too high. Flooding can lead to starting problems, rough idle, and increased fuel consumption.

If you suspect that your carburetor’s float needle valve is not functioning properly, there are a few common problems to look for:

- Worn or damaged needle valve: Over time, the needle valve can become worn or damaged, which can cause it to leak fuel even when it is closed.

- Damaged needle valve seat: The needle valve seat is where the needle valve makes contact with the carburetor bowl. If the seat is damaged, it can prevent the needle valve from sealing properly, leading to fuel leaks.

- Incorrect float level: The float level can become misadjusted over time. An incorrect float level can cause the needle valve to open or close prematurely, resulting in fuel starvation or flooding.

If you are experiencing carburetor problems and suspect that the float needle valve may be the culprit, it is important to check and adjust the float level. This is a relatively simple procedure that can be done with a few basic tools. By ensuring that your float needle valve is functioning properly, you can optimize your carburetor’s performance and keep your engine running smoothly.

Float Needle Valve Seat: A Critical Sealing Surface

As mentioned before, the float needle valve regulates the flow of fuel into the carburetor’s bowl. However, behind this essential component lies a critical sealing surface: the float needle valve seat.

Imagine this: You place a glass of water on a table and carefully turn it upside down. If the base of the glass is smooth and even, water remains trapped inside, defying gravity. Similarly, the float needle valve seat works in tandem with the needle valve to prevent fuel leakage.

When the float rises, it gently presses the needle valve onto the seat, sealing the opening and interrupting fuel flow. This delicate balance ensures that the fuel level in the bowl remains precise, ready to be drawn into the engine when needed.

However, wear and damage can compromise this critical sealing surface. A scratched or deformed seat may allow fuel to seep past the needle valve, causing a rich fuel mixture that can lead to engine performance issues.

To remedy this problem, mechanics often need to replace both the float needle valve and its seat. By ensuring a perfect seal, the carburetor can accurately control fuel flow, leading to optimal engine operation. So, don’t underestimate the importance of a well-seated float needle valve and its essential sealing surface. Regular maintenance and timely repairs can keep your carburetor running smoothly for years to come.

Float Tang: Adjusting the Float Level

The float tang is a small, adjustable tab on the float that plays a crucial role in regulating the fuel level in the carburetor. It’s essentially the “control knob” that governs the flow of gasoline into the fuel bowl.

Imagine the carburetor as a miniature reservoir filled with gasoline. The float acts as a cork that floats on the fuel’s surface. As the fuel level rises, the float moves upward, pushing against the float tang. This pressure causes the tang to bend and close the float needle valve, which is connected to the fuel inlet seat.

By adjusting the float tang, you can fine-tune the float level. If the tang is too long, the float will rise too high and shut off the fuel flow prematurely, starving the engine of gasoline. Conversely, if the tang is too short, the float will not rise enough, allowing too much fuel into the bowl and potentially causing flooding.

Proper float level is essential for your carburetor’s performance. Too little fuel, and your engine will hesitate and misfire. Too much, and you’ll experience flooding, fuel consumption issues, and a rough-running engine.

To adjust the float tang, use a small pair of pliers or tweezers. Gently bend the tang up or down to change the float’s buoyancy. Be precise and make small adjustments at a time, testing the carburetor’s performance between each tweak.

Don’t underestimate the importance of a properly adjusted float tang. It’s the key to maintaining the optimal fuel level, ensuring a smooth-running engine that powers you down the road with ease.

Fuel Inlet Seat: Ensuring a Leak-Free Connection

In the intricate world of a carburetor’s inner workings, the fuel inlet seat plays a critical role in maintaining a leak-free connection. It’s a small but mighty component that effortlessly prevents fuel from seeping out, safeguarding your engine’s performance and your peace of mind.

Imagine your carburetor as a miniature gas station with a steady flow of fuel. The fuel inlet seat acts as the gatekeeper at the entrance, diligently checking that every drop of fuel entering the carburetor finds its rightful place. A poorly seated fuel inlet seat, on the other hand, is like a faulty faucet, allowing precious fuel to escape and potentially causing performance issues.

This unsung hero ensures that the fuel is delivered to the carburetor’s float bowl at the correct pressure. This pressure is crucial for proper fuel metering and mixture formation. Without a well-seated fuel inlet seat, fuel pressure can fluctuate, leading to a lean or rich fuel mixture, affecting your engine’s efficiency and power output.

Moreover, a leaky fuel inlet seat can lead to an unwanted fuel odor, signaling a potential fire hazard. Fuel spills can also attract debris and dirt, further compromising the carburetor’s performance.

Identifying a faulty fuel inlet seat can be tricky, but there are a few telltale signs. If you notice a persistent fuel smell around the carburetor or fuel leaks from the carburetor’s base, it’s time to investigate the fuel inlet seat. A visual inspection can also reveal any visible damage or wear.

Replacing a fuel inlet seat is a relatively simple task that can restore your carburetor’s health. Follow the carburetor manufacturer’s instructions carefully to ensure a proper installation and a leak-free connection.

Remember, a well-maintained fuel inlet seat is the cornerstone of a healthy carburetor. Like the unsung hero it is, it ensures a smooth and efficient flow of fuel, keeping your engine running at its peak performance and giving you peace of mind.

Troubleshooting Float Level Issues: The Culprits Behind Carburetor Mishaps

Every carburetor relies on a precise balance of fuel and air to ensure optimal engine performance. The float level, a crucial component within the carburetor, plays a pivotal role in this delicate equilibrium. However, various factors can disrupt the float level, leading to a host of engine problems.

Worn or Damaged Components

With the passage of time, the constant movement of the float can cause its components to wear out. A deteriorated float or a malfunctioning float needle valve can hinder the valve’s ability to seat properly, resulting in excessive fuel flow and potential flooding.

Debris and Contaminants

Unfortunately, carburetors are not immune to the invasion of foreign substances. Tiny particles of dirt and sediment can find their way into the fuel system, clogging the float needle valve seat or hindering the float’s movement. These obstructions disrupt the float’s ability to accurately regulate fuel flow.

Float Tang Misalignment

The float tang is a small adjustment tab that allows for fine-tuning of the float level. If the tang becomes bent or misaligned, it can throw off the float’s ability to control fuel flow. This can lead to either fuel starvation or flooding, depending on the nature of the misalignment.

Identifying the Problem

To pinpoint the root cause of float level issues, a thorough inspection of the carburetor is necessary. Examine the float for any signs of damage or wear, and ensure that the needle valve and its seat are free of debris and pitting. Additionally, check the fuel inlet seat for proper sealing.

Addressing the Problem

Once the culprit has been identified, it’s time to address the issue. Replace any worn or damaged components, such as the float or needle valve. Clean the carburetor thoroughly to remove any debris, and carefully adjust the float tang to restore the proper fuel level.

Checking and Adjusting the Float Level: A Step-by-Step Guide

In the heart of a carburetor lies a crucial component—the float level. Maintaining its accuracy ensures the smooth operation of your engine and prevents fuel-related issues. Adjusting the float level requires a meticulous approach, and this guide will walk you through the steps involved in measuring and adjusting it on different carburetor models.

Tools and Materials You’ll Need:

- Vernier caliper or ruler

- Screwdriver or wrench (size varies with carburetor model)

Step-by-Step Instructions:

-

Locate the float bowl: The float bowl is usually located at the bottom or side of the carburetor. It’s a metal or plastic chamber that houses the float.

-

Remove the float bowl: Carefully remove the bolts or screws holding the float bowl in place. Be cautious to avoid damaging the gasket.

-

****Measure the float height:** With the float bowl removed, use a Vernier caliper or ruler to measure the distance from the top of the float to the carburetor body’s float bowl mounting surface.

-

****Compare with specifications:** Refer to the carburetor manufacturer’s specifications to determine the correct float height. The typical range is between 10mm and 25mm.

-

****Adjust the float height:** If the measured height differs from the specifications, you need to adjust the float level. This is usually done by bending the float tang.

- To raise the height: Bend the float tang downward.

- To lower the height: Bend the float tang upward.

- ****Reinstall the float bowl:** Once you’ve adjusted the float level, reinstall the float bowl. Tighten the bolts or screws snugly, being careful not to overtighten.

Tips:

- Always check the float for damage or leaks before adjusting it.

- If the float is damaged or leaking, replace it.

- Reinstall the float bowl with a new gasket to ensure a proper seal.

- If you’re not confident in adjusting the float level yourself, consult a qualified mechanic.

Consequences of Incorrect Float Level: ** Fuel Starvation and Flooding

The float level plays a crucial role in maintaining optimal carburetor performance. An incorrect float level can lead to a range of problems that disrupt the engine’s operation and airflow. Understanding the consequences of an improper float level is essential for keeping your vehicle running smoothly.

Fuel Starvation

When the float level is set too low, the float needle valve may not close all the way, allowing too much fuel to enter the carburetor bowl. This results in fuel starvation as the engine doesn’t receive enough fuel to operate properly. Symptoms of fuel starvation include engine hesitation, stumbling, or difficulty starting. It can also lead to engine damage if the fuel mixture becomes too lean.

Flooding

On the other hand, if the float level is set too high, the float needle valve may not open fully, preventing fuel from entering the carburetor bowl. This leads to flooding, as excessive fuel accumulates in the bowl and spills into the engine. Symptoms of flooding include engine difficulty starting, rough idling, and black smoke from the exhaust. Flooding can also foul spark plugs and damage the engine if left unchecked.

Importance of Proper Float Level Adjustment

Maintaining the correct float level is essential to prevent both fuel starvation and flooding. An incorrectly set float level can have significant consequences for engine performance, leading to reduced power, poor fuel economy, and potential engine damage. Therefore, it’s crucial to regularly check and adjust the float level according to the manufacturer’s specifications to ensure optimal carburetor operation.

Advanced Troubleshooting Techniques for Float Level Issues

In the intricate world of carburetor tuning, the float level serves as the heart of fuel regulation, ensuring a steady flow of fuel for optimal engine performance. However, even with meticulous attention to the aforementioned components, you may encounter complex float level issues that require advanced troubleshooting techniques.

Pinpointing the Problem

When faced with stubborn float level dilemmas, systematic troubleshooting is key. First, re-examine the basic components described earlier. Check for worn seals, clogged passages, and damaged components. If everything appears in order, it’s time to delve deeper.

Inspecting the Float

The float itself can be a source of difficulties. It should float effortlessly when submerged in fuel. Any sign of leaks, cracks, or buoyancy issues indicates a compromised float. Replace it promptly.

Fuel Level Measurement Precision

Accuracy is paramount when measuring fuel levels. Ensure the carburetor is level and use a transparent tube to observe the fuel height precisely. Any discrepancies from specified levels point to an adjustment issue or a potential problem elsewhere.

Advanced Tools and Techniques

In certain cases, specialized tools may aid in troubleshooting. Consider using a vacuum gauge to assess fuel flow dynamics or a fuel pressure tester to check for pressure variations that can affect float level stability.

Expert Consultation and Precision Tuning

If all else fails, don’t hesitate to seek professional advice from experienced carburetors. With their expertise and access to advanced diagnostic tools, they can pinpoint the underlying cause and provide tailored solutions.

Remember, a proper float level is the cornerstone of carburetor harmony. By utilizing these advanced troubleshooting techniques and seeking professional assistance when necessary, you can restore your engine’s fuel regulation to its peak performance.