Essential Considerations For Lowered Truck Owners: Pinion Angle, Driveline Geometry, And More

Lowered truck owners must consider pinion angle and driveline geometry. The differential, driveshaft, and axle transmit power, with the pinion angle affecting power delivery and vibration prevention. U-joints ensure smooth driveshaft rotation and depend on proper pinion angle for optimal performance. Altered suspension affects driveline geometry, potentially causing vibration or damage. Transaxles integrate differential and transmission, also impacting driveline angle. Rear-wheel drive systems require specific driveshaft length and pinion angle, while axles support wheels and transmit power, interacting with the differential and driveshaft.

Pinion Angle and Driveline Geometry: The Key to a Smooth Ride in Lowered Trucks

Imagine this: you’ve lowered your dream truck, giving it that sleek and aggressive stance you’ve always desired. But as you hit the road, a persistent vibration creeps up, marring the experience. What gives? The culprit may lie beneath your truck in the intricate world of pinion angle and driveline geometry.

Understanding the Driveline

Your truck’s driveline is a symphony of components, transmitting power from the engine to the wheels. The differential, the heart of the driveline, splits power to the left and right wheels. It connects to the driveshaft, a rotating bridge, that carries power to the axle, which supports the wheels.

Pinion Angle: The Critical Angle

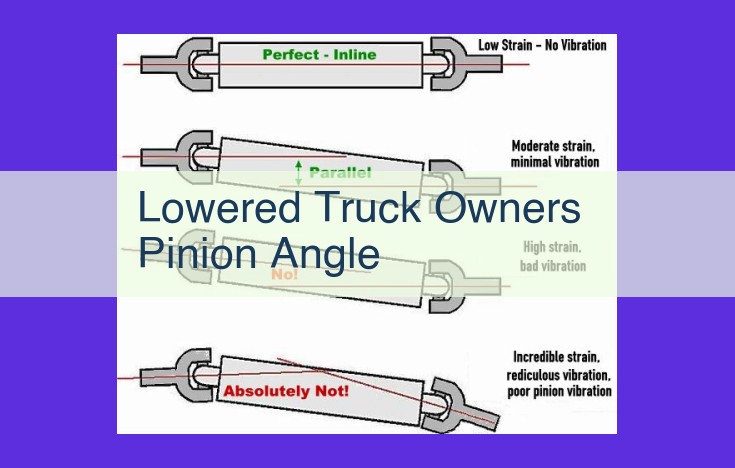

Crucial to this harmonious operation is the pinion angle, the angle at which the pinion gear of the differential meets the driveshaft. This angle affects the alignment of the U-joints, which connect the differential, driveshaft, and axle. Proper pinion angle ensures smooth power delivery and vibration-free operation.

Lowering Your Truck: A Delicate Balance

Lowering your suspension alters the geometry of the driveline, changing pinion angle and U-joint alignment. Improper angles can lead to vibrations, driveline damage, and compromised performance.

The Importance of Proper Pinion Angle

Maintaining proper pinion angle is paramount for vibration reduction. U-joints can only accommodate a limited amount of angle deviation; excessive angles stress the joints, leading to premature failure.

Know Your Driveline

Depending on your truck’s drivetrain configuration (rear-wheel drive or transaxle), the driveline components and their relationships vary. Understanding your specific setup will help you diagnose and resolve any driveline issues.

Pinion angle and driveline geometry are key factors in ensuring a smooth and trouble-free driving experience in lowered trucks. By understanding their importance and maintaining proper angles, you can enjoy the benefits of a lowered ride without compromising performance or comfort.

The Differential: Power Transmission’s Heartbeat

At the core of your lowered truck’s power transmission system lies a vital component: the differential. It’s the maestro that orchestrates power distribution to your wheels, ensuring a smooth and efficient ride.

The differential is the link between the axle, driveshaft, and U-joints. It houses gears that allow the wheels on each side of the axle to rotate at different speeds, a crucial feature for cornering smoothly.

However, the differential’s story doesn’t end there. It plays a pivotal role in maintaining pinion angle, which is the angle at which the driveshaft meets the differential. Pinion angle is crucial for vibration reduction. If the pinion angle is off, it can cause driveline vibrations that may eventually damage your truck.

So, the differential acts as the heart of power transmission, ensuring that power is delivered smoothly to your wheels while maintaining the proper pinion angle. Understanding its function is essential for keeping your lowered truck running like a well-oiled machine.

Driveshaft: The Conduit of Power

In the realm of automotive engineering, the driveshaft stands as a pivotal component, bridging the power gap between the differential and the axles. Its primary mission is to transmit rotational force from the differential to the wheels, enabling them to propel the vehicle forward.

Design and Function

The driveshaft is an elongated, cylindrical shaft that consists of universal joints at each end. These joints facilitate the transfer of motion between the differential, which is mounted on the transmission, and the axles, which are positioned at the wheels. As the differential rotates, it imparts torque to the driveshaft, which then transmits this power to the axles.

Impact of Lowered Suspension

When a truck’s suspension is lowered, it can have a significant impact on the driveline angle. This is because the lowered suspension alters the vertical alignment of the driveshaft, causing it to operate at a different angle than it was designed for.

As the suspension is lowered, the driveshaft becomes more steeply inclined, which can lead to excessive vibration. This is due to the increased angularity of the universal joints, which puts additional stress on their components. Furthermore, improper driveline angles can also result in premature wear and potential damage to the driveshaft and other driveline components.

Pinion Angle: The Critical Angle of Engagement

When it comes to lowered trucks, understanding pinion angle and driveline geometry is crucial for smooth operation. The pinion angle is the angle at which the driveshaft meets the differential. This angle is essential for proper power transmission from the engine to the wheels.

The differential is the heart of the power transmission system, distributing power to the wheels. It connects to the driveshaft, which bridges power from the differential to the axle. The axle transmits power to the wheels, completing the driveline.

Pinion angle directly affects driveshaft orientation and U-joint alignment. If the pinion angle is incorrect, vibrations can occur due to misalignment of the driveshaft and U-joints. This can lead to premature wear and damage to driveline components.

Proper pinion angle is crucial to minimize vibrations and ensure smooth power delivery. By carefully adjusting the pinion angle to the recommended specifications, you can optimize driveline performance and extend the lifespan of your lowered truck.

U-Joints: The Unsung Heroes of Driveline Harmony

In the realm of lowered trucks, U-joints stand as the silent warriors, ensuring a smooth and harmonious dance of power transmission. These unsung heroes, located at the heart of your driveline, connect the differential, driveshaft, and axle, playing a crucial role in maintaining the optimum driveline geometry so essential for a vibration-free ride.

What is a U-Joint and How Does it Work?

At first glance, U-joints may seem like unassuming components, but their ingenious design and flawless execution make them marvels of automotive engineering. Universal joints, as their name suggests, allow the driveshaft to rotate at various angles while maintaining a constant power transmission.

Inside these compact marvels lies a cross-shaped yoke and four needle bearings. The driveshaft is connected to one yoke, and the axle to the other. As the driveshaft rotates, the cross-shaped yoke slides back and forth within the bearing cups, allowing the shaft to articulate around corners and uneven terrain.

The Impact of U-Joints on Driveline Angle

The relationship between U-joints and driveline angle is a delicate balance. When the suspension is lowered, the angle of the driveshaft changes, which in turn affects the operating angle of the U-joints. If the angle becomes too severe, the U-joints experience excessive stress, leading to premature wear and potential failure.

Why Proper U-Joint Alignment is Paramount

Proper U-joint alignment is paramount for several reasons:

- Reduced Vibration: Excessive U-joint angles can cause vibration throughout the drivetrain. This vibration can be transmitted to the cabin, resulting in an uncomfortable and noisy ride.

- Extended U-Joint Life: A properly aligned U-joint operates within its optimal operating range, reducing wear and tear and prolonging its lifespan.

- Improved Performance: A well-aligned driveline ensures efficient power transmission, maximizing performance and fuel economy.

Signs of U-Joint Problems

If you suspect that your U-joints may be experiencing issues, be on the lookout for these signs:

- Driveline Vibration: Excessive vibration while driving, especially at higher speeds, can indicate a problem with the U-joints.

- Joint Noise: Worn or damaged U-joints may produce a clunking or snapping sound when turning or accelerating.

- Leaking Grease: A leaking U-joint may necessitate replacement.

U-joints, though small in stature, play a crucial role in the smooth operation of your lowered truck’s driveline. By understanding their function and maintaining proper alignment, you can ensure a vibration-free and extended lifespan for your drivetrain. Remember, the health of your U-joints is the key to a harmonious and enjoyable driving experience.

Lowered Suspension and Driveline Angle: A Balancing Act

Modifying the suspension of your truck to lower its stance can enhance its appearance and handling, but it also introduces potential challenges to the vehicle’s driveline geometry. Lowering the suspension alters the angle of the driveshaft, which connects the transmission to the differential, and can lead to vibration and premature driveline component failure.

Pinion Angle and Driveline Angle

The pinion angle refers to the angle at which the driveshaft meets the differential. This angle is crucial for optimal driveline performance, as it affects the orientation of the U-joints, which allow the driveshaft to rotate smoothly.

Impact of Lowered Suspension

Lowering the suspension changes the driveshaft angle, which in turn alters the pinion angle. If the pinion angle is too steep or too shallow, it can cause vibration, excessive wear on the U-joints, and potential damage to the driveshaft or differential.

Consequences of Improper Angles

Improper driveline angles can result in several issues, including:

- Vibration: Excessive vibration caused by misaligned U-joints can be transmitted throughout the vehicle, creating discomfort for passengers and potentially damaging other components.

- Premature Wear: Misaligned U-joints experience increased friction, leading to premature wear and failure.

- Driveline Damage: Severe misalignment can cause excessive stress on the driveshaft and differential, potentially leading to costly repairs or even complete failure.

Balancing Lowered Suspension and Driveline Geometry

To mitigate these challenges and enjoy the benefits of a lowered suspension, it is crucial to take steps to maintain proper driveline geometry. This may involve adjusting the pinion angle, replacing worn U-joints, or modifying the driveshaft length. It is highly recommended to seek professional assistance to ensure that these adjustments are performed accurately and effectively.

Lowering suspension on a truck can be a rewarding modification, but it is essential to understand the potential impact on driveline geometry. By addressing pinion angle and driveline angles through proper adjustments and maintenance, you can preserve the performance and longevity of your vehicle while enjoying the aesthetic benefits of a lowered stance.

Transaxle: The Union of Differential and Transmission

In the realm of automotive engineering, the transaxle stands as a unique and intricate component. It elegantly combines the functionalities of both a differential and a transmission, making it an essential element in the powertrain systems of various vehicles.

The transaxle’s primary role lies in managing the transfer of power from the engine to the wheels. This intricate system comprises a series of gears and shafts that transmit power and adjust its speed and direction. By seamlessly integrating the differential and transmission functions, the transaxle optimizes power delivery and enhances the overall driving experience.

Impact on Driveline Angle and Vibration

One of the significant implications of employing a transaxle is its impact on driveline angle. The driveline angle refers to the angle at which the driveshaft operates. When a vehicle is lowered, the driveline angle can become steeper, potentially leading to vibrations and premature wear of driveline components.

However, the transaxle’s placement within the vehicle helps mitigate these adverse effects by adjusting the driveline angle. By optimizing the alignment of the driveshaft, the transaxle reduces vibrations and ensures smooth power delivery.

The transaxle is an indispensable component in modern vehicles, combining the functionalities of differential and transmission. Its ingenious design not only facilitates efficient power transfer but also plays a vital role in maintaining optimal driveline angle and minimizing vibrations. By harmonizing these critical functions, the transaxle contributes to the overall driving performance and longevity of the vehicle.

Rear-Wheel Drive: The Classic Powertrain Configuration

In the realm of automotive engineering, the rear-wheel drive system holds a special place as a timeless and efficient powertrain configuration. At the heart of this setup lies a trio of critical components: differential, driveshaft, and axle. Each plays a vital role in transmitting power from the engine to the rear wheels, ensuring a smooth and effective driving experience.

The differential acts as the centerpiece of the powertrain, responsible for distributing power evenly between the left and right wheels. It also enables them to rotate at different speeds, which is crucial for navigating curves and corners. From the differential, a driveshaft extends backward, connecting it to the rear axle. This rotating shaft bridges the gap, transmitting power to the wheels.

The axle serves as the foundation for the rear wheels, supporting their weight and ensuring their proper alignment. It also houses the differential and driveshaft, providing a robust and stable base for power delivery.

Driveshaft Length and Pinion Angle: The Key Elements

In a rear-wheel drive system, the length of the driveshaft is of utmost importance. It must be precisely calibrated to match the distance between the differential and the axle. An incorrect driveshaft length can lead to misalignment between the differential and the axle, resulting in excessive vibrations and premature wear.

Equally crucial is the pinion angle, which refers to the angle at which the driveshaft meets the differential. Proper pinion angle is essential for minimizing vibrations and ensuring smooth engagement between the differential and the driveshaft. When the suspension is lowered, it can impact the pinion angle, potentially causing vibrations and driveline problems.

Maintaining a Conducive Environment for Rear-Wheel Drive

To ensure the longevity and efficiency of a rear-wheel drive system, regular maintenance is vital. This includes inspecting and servicing the differential, driveshaft, and axle regularly. Additionally, monitoring the pinion angle is crucial to prevent premature wear and costly repairs.

By understanding the intricacies of the rear-wheel drive powertrain configuration and adhering to proper maintenance practices, you can ensure that your vehicle delivers reliable and trouble-free performance for many miles to come.

The Axle: Powerhouse of Wheel Support and Power Transmission

Nestled beneath your lowered truck, the axle assumes a pivotal role in supporting your wheels and transmitting power to them. This unsung hero forms an integral link between the differential, the driveshaft, and the pinion angle, ensuring that your truck runs smoothly and efficiently.

The axle is responsible for keeping your wheels firmly in place, allowing you to navigate turns, bumps, and uneven terrain with ease. It acts as a sturdy foundation, ensuring that your truck remains stable and balanced, even on challenging roads.

Furthermore, the axle plays a crucial part in delivering power from the differential to the wheels. It serves as a conduit, transmitting torque to the wheels, so you can accelerate, climb hills, and conquer any obstacle that comes your way.

The axle’s relationship with the differential, driveshaft, and pinion angle is intricate and interdependent. The pinion angle, which determines the driveshaft’s orientation, affects the alignment of the U-joints. If the pinion angle is incorrect, it can lead to vibrations, premature wear, and even driveline damage.

By understanding the role of the axle and its impact on driveline geometry, you can ensure that your lowered truck delivers optimal performance. Whether you’re tackling off-road adventures or cruising down the highway, a properly maintained axle will provide you with a comfortable, safe, and enjoyable ride.