The Ultimate Fuel Pump Priming Guide: Techniques, Applications, And Troubleshooting

A fuel pump priming guide provides a comprehensive understanding of the significance and methods of priming a fuel pump for the proper functioning of an engine. It covers different priming techniques including vacuum priming, manual priming, and electrical priming, explaining their processes and applications. The guide also explores related concepts such as the priming port, fuel filter, and fuel injection system, and offers guidance on choosing the appropriate priming method. Additionally, it addresses common issues and troubleshooting tips, highlighting the importance of proper priming for engine performance and longevity.

Fuel Pump Priming: A Necessity for Engine Functioning

The heart of your vehicle, the engine, relies on a steady supply of fuel to power its pistons and keep you moving. And to ensure that fuel reaches the engine efficiently, fuel pump priming plays a crucial role. Think of it as giving your engine’s fuel system a jumpstart, preparing it for the task ahead.

Fuel pump priming is essential because it fills the fuel system with fuel, eliminating air pockets that could cause the engine to hesitate or even stall. Without proper priming, the fuel pump may struggle to draw fuel, leading to a loss of engine power and potential damage to the fuel system.

Methods of Fuel Pump Priming

There are several methods to prime a fuel pump, depending on the vehicle’s fuel system design. Here are the most common techniques:

-

Vacuum Priming: In this method, a vacuum is created within the fuel supply line using a priming port, which draws fuel into the system.

-

Manual Priming: This involves using a hand pump or primer bulb to physically pump fuel into the fuel lines.

-

Electrical Priming: With this method, an electric fuel pump is activated to circulate fuel through the system, eliminating air pockets.

Choosing the Appropriate Priming Method

The best priming method depends on the specific fuel system and vehicle. Consult your vehicle’s owner’s manual or refer to the following guidelines:

- Vacuum Priming: Common in older vehicles with carburetors.

- Manual Priming: Suitable for vehicles with older fuel systems or those with a separate priming bulb.

- Electrical Priming: Used in modern vehicles with electronic fuel injection systems.

Common Issues and Troubleshooting

While priming can be straightforward, certain issues may arise:

- Air Trapped in Fuel Lines: If air remains in the fuel lines after priming, it can cause the engine to hesitate or stall. Bleed the fuel system by opening a bleed screw to release any trapped air.

- Faulty Fuel Pump: If the fuel pump is damaged or malfunctioning, it may not be able to draw fuel efficiently. Replace the fuel pump as necessary.

Fuel pump priming is a vital step in ensuring your engine runs smoothly and efficiently. By eliminating air pockets and filling the fuel system with fuel, priming prepares your vehicle for a seamless driving experience. Neglecting this crucial task can lead to engine problems and potential damage down the road. So, remember to prime your fuel pump before starting your engine and enjoy a worry-free drive.

Methods of Fuel Pump Priming

To ensure a smooth and efficient engine operation, proper fuel pump priming is essential. There are various methods employed to prime a fuel pump, each tailored to specific fuel systems and vehicle designs. Let’s delve into the different priming techniques.

Vacuum Priming

Vacuum priming is commonly used in older vehicles with mechanical fuel pumps. By activating the engine while the priming port is open, a vacuum is created that draws fuel from the tank and fills the fuel lines. As the vacuum builds, the fuel level in the priming port gradually rises, indicating proper priming.

Manual Priming

Manual priming is a straightforward method employed in some fuel systems. It involves using a hand pump or primer bulb located on the fuel line or near the fuel filter. By manually pumping, fuel is pushed through the system, displacing any air pockets and ensuring a consistent fuel flow.

Electrical Priming

Electrical priming is employed in vehicles with electric fuel pumps. An electric fuel pump is activated, typically upon turning the ignition key, to circulate fuel through the system. This method effectively primes the pump and pressurizes the fuel lines, preparing the engine for immediate starting.

In selecting the appropriate priming method, it’s crucial to consult the vehicle’s service manual or consult with a qualified mechanic. Each method has its own specific requirements and limitations, and choosing the correct one will ensure optimal engine performance and longevity.

Vacuum Priming: A Vital Technique for Engine Startup

When preparing your vehicle for a seamless start, vacuum priming plays a crucial role in ensuring the efficient flow of fuel to your engine. This technique relies on the vacuum created by the engine’s intake manifold to draw fuel from the tank.

How Vacuum Priming Works

Vacuum priming capitalizes on the negative pressure generated in the intake manifold when the engine cranks. This vacuum is channeled through a dedicated priming port on the fuel pump. As the intake valve opens, the vacuum sucks fuel from the tank and into the pump, initiating the fuel flow.

To perform vacuum priming, you’ll need to locate the priming port on the fuel pump. Typically, this port is either a small hole or a nipple with a hose attached. Using a suitable tool like a vacuum pump or a hand pump, create a vacuum in the priming port. This vacuum draws fuel from the tank, filling the fuel pump and the fuel lines.

Once the fuel pump is filled, the vacuum will diminish, allowing the fuel to flow naturally through the fuel lines. The engine can then be started without any issues, as the fuel supply is now established.

Benefits of Vacuum Priming

Vacuum priming offers several advantages:

- Efficiency: It’s a quick and efficient method of priming the fuel pump.

- Cost-effectiveness: It doesn’t require any specialized equipment or tools.

- Simplicity: The process is straightforward and can be easily performed by anyone.

Important Considerations

While vacuum priming is an effective technique, it’s essential to note a few considerations:

- Vehicle Compatibility: Vacuum priming is not suitable for all vehicles. It’s primarily applicable to older vehicles with carburetor-based fuel systems.

- Fuel Tank Level: The fuel tank should have sufficient fuel to ensure proper priming.

- Air Leaks: Any air leaks in the fuel lines or connections can hinder vacuum priming. Check for leaks and seal them if necessary.

Manual Priming: A Hands-On Approach to Fuel System Health

When it comes to keeping your engine humming smoothly, fuel pump priming is an often overlooked but crucial step. Manual priming, a hands-on technique, involves physically pumping fuel into your fuel system to prime the pump and ensure proper engine operation.

How it Works:

Manual priming utilizes a hand pump or primer bulb connected to the fuel line. By applying pressure to the bulb, you force fuel through the lines, expelling any trapped air and filling the fuel filter. This process ensures that the fuel pump has an ample supply of fuel to draw upon.

Steps Involved:

- Locate the Primer Bulb: Typically found near the fuel filter or carburetor, the primer bulb is a hand-sized rubber device.

- Apply Pressure: Grip the bulb firmly and squeeze it repeatedly. Continue pumping until you feel resistance, indicating the system is primed.

- Check for Leaks: Inspect the fuel lines and connections for any signs of leakage. If you notice any, tighten them or replace faulty components.

Benefits of Manual Priming:

- Prevents Engine Airlocks: Trapped air in fuel lines can cause airlocks, preventing fuel from reaching the engine. Manual priming eliminates these air pockets, ensuring a smooth flow of fuel.

- Improves Engine Performance: A properly primed fuel system ensures consistent fuel delivery, resulting in optimal engine performance and reduced emissions.

- Protects Fuel Pump: Running a fuel pump without sufficient fuel can damage its components. Manual priming ensures the pump has a constant supply of fuel to prevent overheating.

When is Manual Priming Required?

- New Fuel Filter Installation: Installing a new fuel filter removes fuel from the system, requiring manual priming to replenish it.

- Empty Fuel Tank: If your fuel tank runs dry, air enters the fuel lines. Manual priming purges this air and restores fuel flow.

- Vehicle Storage: Extended vehicle storage can cause fuel to evaporate, necessitating manual priming before starting the engine.

- Troubleshooting Fuel System Issues: If you experience engine stalling or difficulty starting, manual priming can help identify potential fuel system problems.

Electrical Priming: Facilitating Fuel Flow with Electric Assistance

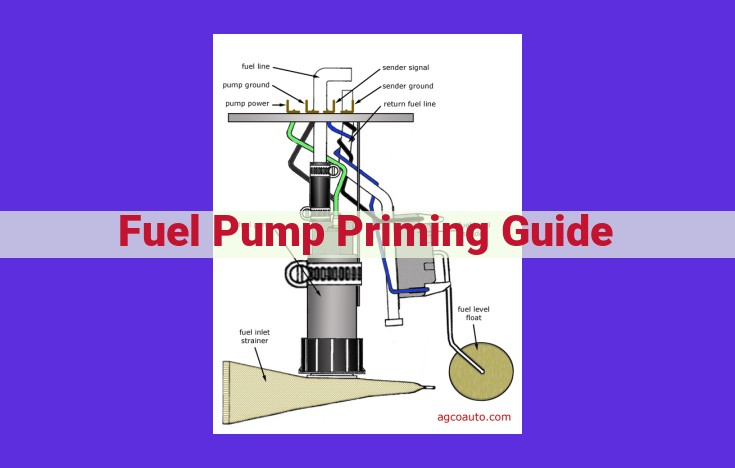

Electrical priming employs an electric fuel pump to circulate fuel through the system. This method is common in modern vehicles with electronically controlled fuel systems. The electric fuel pump is located in the fuel tank and is activated by the vehicle’s electronic control unit (ECU).

When the ignition switch is turned on, the ECU sends a signal to the electric fuel pump. The pump begins to operate, drawing fuel from the tank and circulating it through the fuel lines. This action builds up fuel pressure in the system, ensuring a steady supply of fuel to the engine.

Electrical priming offers several advantages. It is a quick and efficient way to prime the fuel pump, particularly in vehicles where the fuel tank is located far from the engine. Additionally, electrical priming eliminates the need for manual pumping or vacuum priming, making it more convenient for the driver.

To ensure proper electrical priming, the electric fuel pump must be in good working condition. If the fuel pump is faulty or damaged, it may not be able to generate sufficient fuel pressure, leading to starting problems or engine performance issues. Regular maintenance and replacement of the electric fuel pump as recommended by the vehicle manufacturer are essential to maintain optimal fuel pump priming and overall engine performance.

Fuel Pump Priming: Unveiling the Intricacies of Engine Functioning

When it comes to the smooth operation of your vehicle’s engine, fuel pump priming plays a pivotal role. It’s like the priming of a canvas before an artist begins their masterpiece, ensuring the engine has the necessary fuel to ignite and power your journey.

Fuel Pump Priming: A Foundation for Flawless Engine Performance

Just as a house needs a solid foundation, your engine relies on properly primed fuel pumps to deliver a steady supply of fuel. Without priming, air bubbles can accumulate in the fuel lines, hindering the flow of fuel and leading to engine performance issues. This can result in a rough idle, stalling, or even a complete inability to start your vehicle.

Methods of Fuel Pump Priming: A Primer to Choose Wisely

Various methods exist for priming fuel pumps, each tailored to specific vehicle designs. Let’s unravel the most common approaches:

-

Vacuum Priming: This technique utilizes the engine’s vacuum to draw fuel into the pump. A priming port on the pump connects to a vacuum line, creating a suction that fills the pump with fuel.

-

Manual Priming: With this method, you physically pump fuel into the fuel system using a hand pump or primer bulb located near the fuel filter. This is often used in older vehicles or in cases where vacuum priming is not possible.

-

Electrical Priming: Certain fuel pumps incorporate an electric motor that activates upon ignition, circulating fuel throughout the system without external priming.

Related Concepts: A Lexicon of Fuel Pump Priming Terminology

To fully grasp fuel pump priming, it’s essential to understand related concepts:

Priming Port: A connection point on the fuel pump that allows vacuum or fuel to enter.

Fuel Pressure Gauge: A device that measures the pressure of fuel in the system, indicating pump performance.

Fuel Filter: A component that traps impurities in the fuel before it reaches the pump, ensuring clean fuel flow.

Bleed Screw: A valve that releases trapped air from the fuel lines after priming.

Fuel Injection System: A system that sprays fuel directly into the engine cylinders, relying on a primed fuel pump to deliver fuel at the required pressure.

Carburetor: A device that mixes air and fuel before entering the engine, also dependent on a properly primed fuel pump.

Choosing the Appropriate Priming Method: A Primer for Success

Selecting the right priming method depends on the specific fuel system and vehicle design. Consult your vehicle’s owner’s manual or a qualified mechanic for the recommended priming procedure.

Choosing the Appropriate Fuel Pump Priming Method

When it comes to priming a fuel pump, the method you choose should align with the specific fuel system and vehicle you’re working on. Here’s a guide to help you make an informed decision:

Gasoline Engines:

-

Vacuum priming is commonly used in gasoline engines with carburetors. The engine creates a vacuum through the priming port, drawing fuel into the system. This method is suitable for vehicles that have been idle for an extended period.

-

Manual priming involves using a hand pump or primer bulb to physically pump fuel into the fuel lines. This method is often employed on older vehicles or those with mechanical fuel pumps.

Diesel Engines:

- Electrical priming is typically used in modern diesel engines with electronic fuel injection systems. An electric fuel pump is activated to circulate fuel through the system, creating the necessary pressure.

Factors to Consider:

Beyond the engine type, here are key factors to consider when selecting a priming method:

- Fuel system design: Some fuel systems may be more compatible with certain priming methods.

- Accessibility of the priming port: Vacuum priming requires access to a priming port, which may not always be readily available.

- Fuel pump type: Electric fuel pumps require an electrical connection and may be less suitable for manual priming.

- Vehicle condition: If the vehicle has been sitting idle for prolonged periods, vacuum priming may not be sufficient to overcome air build-up in the fuel lines.

Additional Considerations:

Remember these additional tips for successful fuel pump priming:

- Use fresh fuel: Old or contaminated fuel can hinder priming efforts.

- Check for leaks: Make sure there are no fuel leaks or loose connections in the fuel system.

- Be patient: Priming can take several attempts, especially for large fuel systems or if there is air trapped in the lines.

By carefully considering the factors outlined above, you can effectively choose the appropriate fuel pump priming method for your specific situation. Proper priming ensures that the engine receives the necessary fuel and operates smoothly for optimal performance.

Common Issues and Troubleshooting

Air Trapped in Fuel Lines

One common priming issue is air trapped in fuel lines. This can occur when the fuel system is opened for repairs or maintenance, allowing air to enter the lines. Air bubbles can block the flow of fuel, preventing the engine from starting or running properly.

Troubleshooting Air Trapped in Fuel Lines:

- Check for leaks: Inspect the fuel lines for any signs of leaks where air could be entering.

- Bleed the fuel lines: Locate the bleed screw on the fuel filter or injection system and open it slightly to release trapped air. Close the bleed screw once fuel starts to flow out without bubbles.

- Use a vacuum pump: Connect a vacuum pump to the fuel line and apply suction to remove the air.

Faulty Fuel Pump

If proper priming does not resolve the issue, a faulty fuel pump may be the culprit. A faulty fuel pump can fail to deliver adequate fuel pressure or may be unable to prime the system altogether.

Troubleshooting a Faulty Fuel Pump:

- Check fuel pressure: Use a fuel pressure gauge to measure the pressure in the fuel system. Low fuel pressure can indicate a failing fuel pump.

- Listen for the fuel pump: Turn the ignition key to the “on” position and listen for the sound of the fuel pump running. A faint hum or buzzing sound indicates the pump is operating.

- Inspect the fuel filter: A clogged fuel filter can restrict fuel flow to the fuel pump, causing it to fail. Replace the fuel filter regularly as per the manufacturer’s recommendations.