Comprehensive Guide To Optimizing Sump Pump Hole Drilling For Unparalleled Performance

Drilling holes in sump pumps requires careful planning and execution. Determine the appropriate drill bit based on size, shape, and length; optimize drill speed by setting the RPM and feed rate; consider the suitability of different drill types for the task. Prioritize safety with protective gear and ventilation. Plan hole locations, measure depth precisely, and ensure alignment. Select the correct drill bit diameter and material for the sump pump’s fitting. Utilize cooling and lubrication techniques to enhance drill bit performance. Optimize hole spacing and arrangement for effective drainage.

Drill Bit Selection: Size, Shape, and Length

- Emphasize the importance of choosing a drill bit with the correct diameter, length, and shape for the desired hole and material.

Drill Bit Selection: Keys to Drilling Success

When it comes to drilling holes for your sump pump, proper drill bit selection is paramount. It’s not just about grabbing any old bit; choosing the correct size, shape, and length is essential to ensure a clean, precise hole that doesn’t compromise your pump’s performance.

_Size:_ The diameter of your drill bit should match the diameter of the threads on your sump pump fitting. Measuring the threads with a caliper or ruler will give you the exact size you need. Too small a bit will result in a loose connection, while too large a bit will weaken the material around the hole.

_Shape:_ The shape of your drill bit depends on the material you’re drilling into. For concrete or masonry, you’ll need a carbide-tipped bit. For metal, a cobalt or high-speed steel bit is best. And for plastic or wood, a general-purpose bit will do the trick.

_Length:_ The length of your drill bit should be sufficient to penetrate the material and create a hole of the desired depth. Consider the thickness of the material and the distance from the surface to the finished hole. Using a bit that’s too long can cause it to flex or break, while a bit that’s too short may not reach the desired depth.

By following these guidelines, you’ll choose the perfect drill bit for your sump pump installation and create a secure, long-lasting connection.

Drill Speed Optimization: RPM and Feed Rate

- Explain the concept of drill bit speed range and how to set the spindle speed and feed rate for optimal drilling conditions.

Drill Speed Optimization: The Key to Precise and Efficient Sump Pump Installation

In the intricate process of sump pump installation, drill speed optimization plays a crucial role in ensuring the precision and efficiency of the drilling process. Understanding the concept of drill bit speed range, and skillfully setting the spindle speed and feed rate can significantly enhance your drilling experience.

Drilling Speed Range

Every drill bit has a specific speed range within which it operates optimally. This range depends on factors like the material of the drill bit and the workpiece, as well as the diameter of the hole being drilled. Operating outside this range can result in poor hole quality, excessive heat, and premature drill bit failure.

Setting Spindle Speed

The spindle speed refers to the number of revolutions per minute (RPM) of the drill bit. To determine the appropriate spindle speed, consider the diameter of the drill bit and the material being drilled. Consult drill bit manufacturers’ specifications or refer to drill speed charts. Higher speeds are typically recommended for smaller diameter bits and harder materials, while lower speeds are more suitable for larger diameter bits and softer materials.

Setting Feed Rate

The feed rate determines how fast the drill bit advances into the workpiece. A too high feed rate can lead to overheating and bit breakage, while a too low feed rate can result in slow drilling and poor hole quality. The ideal feed rate depends on factors like the drill bit material, the workpiece material, and the spindle speed. Manufacturers’ specifications or drill feed rate charts can provide guidance in selecting the appropriate feed rate.

Optimizing for Efficiency and Precision

By fine-tuning the spindle speed and feed rate, you can maximize drilling efficiency and precision. Correct spindle speed minimizes friction and heat generation, extending the life of the drill bit and ensuring a smooth drilling process. Appropriate feed rate prevents binding and chattering, resulting in clean, burr-free holes.

In essence, understanding and optimizing drill speed is pivotal for successful sump pump installation. By adhering to recommended speed ranges and carefully setting spindle speed and feed rate, you can achieve precise hole drilling, reduce drilling time, and ensure the longevity of your drill bits, ultimately contributing to a well-executed sump pump installation.

Drill Type Options: Choosing the Right Tool for Sump Pump Installation

When drilling holes for sump pump installation, selecting the appropriate type of drill is crucial. Each type offers unique advantages and is suitable for specific drilling tasks:

Drill Press

- Recommended for: Precise, stationary drilling with high torque and depth control.

- Ideal for: Drilling large or deep holes in basements or slabs where precision is paramount.

Hand Drill

- Recommended for: Small, manual drilling tasks with limited power.

- Ideal for: Creating pilot holes or drilling into thin materials where portability is essential.

Power Drill

- Recommended for: Drilling a wider range of holes with variable speed and torque settings.

- Ideal for: Drilling into concrete, metal, or wood, as well as tasks requiring higher power and efficiency.

Impact Drill

- Recommended for: Drilling into hard materials such as concrete or masonry with high impact force.

- Ideal for: Creating large or deep holes in tough surfaces where conventional drilling methods are ineffective.

Choosing the Right Drill

For sump pump installation, a power drill or an impact drill is typically recommended. Power drills provide versatility and variable speed control, while impact drills offer superior force for drilling into concrete or hard surfaces.

Consider the following factors when choosing:

- Hole size and depth: Determine the diameter and depth of holes required for the sump pump mounting bolts.

- Material: Choose a drill type that is compatible with the material you are drilling into (e.g., concrete, wood, metal).

- Power and speed: Select a drill with adequate power and variable speed settings to suit the task and material.

- Portability: Consider the ease of handling and the accessibility of the drilling location.

By selecting the right drill type and optimizing its settings, you can ensure precise and efficient drilling for a successful sump pump installation.

Safety Precautions: Ensuring Protection and Ventilation

Drilling poses certain risks that can be effectively minimized by adhering to essential safety precautions. Protective gear is paramount to safeguard your health during the drilling process. Safety glasses shield your eyes from flying debris, while earplugs or earmuffs protect your hearing from the piercing noise of the drill. Gloves prevent cuts and abrasions, and appropriate clothing reduces the risk of entanglement.

Ventilation is equally crucial. Drilling can release hazardous fumes and dust, especially when working with certain materials. Opening windows and doors, or operating a fan or dust extractor, ensures proper ventilation and minimizes exposure to these harmful elements. By following these safety guidelines, you create a safe work environment, preventing accidents and protecting your well-being.

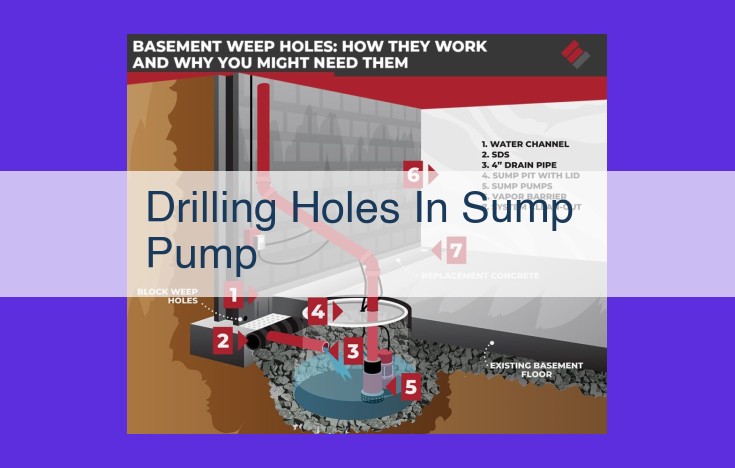

Hole Location Planning: Precise Drilling for Optimal Results

When installing a sump pump, meticulous planning of hole locations is paramount. Proper hole spacing and alignment not only ensure the efficient functioning of the pump but also prevent water pooling and structural issues.

Adequate spacing between holes allows for even weight distribution and prevents the sump pit from becoming overwhelmed during heavy rainfall. Precise alignment ensures that the sump pump can be installed securely and operates without wobbling or vibrating, which can lead to premature failure.

To mark the hole locations accurately, use a pencil or a center punch. Measure the distance between the holes carefully and mark them with precision. A drill template can also be used for added accuracy.

By following these guidelines, you ensure that the sump pump is installed correctly, maximizing its efficiency and extending its lifespan.

Hole Depth Measurement and Control: The Key to Precise Sump Pump Installation

When it comes to installing a sump pump, precision is paramount. One crucial aspect of this process is accurately determining and controlling the depth of the holes drilled for the sump pump fitting. Over-drilling or under-drilling can lead to costly mistakes, compromised performance, and potential safety hazards.

To ensure optimal results, it’s imperative to use precise measuring tools such as hole depth gauges or micrometers. These instruments allow you to accurately gauge the depth of your drilled hole, eliminating the guesswork and reducing the risk of drilling too deep or too shallow.

Over-drilling can create a weakened area in the material, potentially jeopardizing the structural integrity of the sump pump installation. It can also lead to water leakage or reduced efficiency of the pump due to improper fitting. Conversely, under-drilling may result in the sump pump being unable to sit flush against the surface, creating gaps that allow water to seep or preventing proper drainage.

By carefully measuring and controlling hole depth, you can ensure that the sump pump fits snugly and securely, allowing it to function optimally and effectively. This attention to detail will not only enhance the longevity and performance of your sump pump but also provide peace of mind knowing that your home is well-protected from water damage.

Drilling for Drainage: A Precise Guide to Sump Pump Installation

Drilling holes for sump pump fittings requires meticulous planning and execution. Precise hole diameter and alignment are crucial to ensure a secure and functional connection.

The drill bit diameter must match the threads of the sump pump fitting. Using a drill bit that is too small or too large can compromise the seal, leading to leaks or, even worse, a faulty installation.

Alignment is equally important. Drilling at an angle or off-center can create gaps between the fitting and the sump basin, allowing water to bypass the pump. It can also make it difficult to tighten the fitting properly.

To achieve precise diameter and alignment, follow these steps:

- Measure the sump pump fitting’s threads carefully. Use a caliper or micrometer to determine the exact diameter.

- Choose a drill bit that is the same size as the fitting’s threads. Avoid using a bit that is slightly smaller or larger, as it will affect the fit and seal.

- Mark the hole location on the sump basin. Use a level to ensure that the hole is drilled perpendicular to the basin’s surface.

- Drill a pilot hole first. Start with a small drill bit, then gradually increase the size until you reach the desired diameter.

- Check the hole’s alignment frequently using a level. If necessary, adjust the drill bit’s position and re-drill.

- Countersink the hole if needed. This will create a beveled edge that allows the sump pump fitting to sit flush with the basin’s surface.

By following these guidelines, you can ensure that the holes for your sump pump fitting are precise in diameter and alignment, guaranteeing a secure and effective installation that will protect your home from water damage.

Drill Bit Material and Characteristics: A Crucial Consideration for Drilling Precision

Selecting the appropriate drill bit material is paramount when drilling precise holes for sump pump installation. The material of the sump pump and the drilling conditions must be carefully considered to ensure optimal performance and longevity.

Variations in Drill Bit Materials

Drill bits are commonly made from various materials, each with unique properties and applications. High-carbon steel drill bits offer a balance of hardness and toughness, suitable for drilling softer materials such as wood and plastic. High-speed steel drill bits are more durable and can withstand higher temperatures, making them ideal for drilling metal and harder materials. Cobalt alloy drill bits provide exceptional wear resistance and are often used to drill tough materials like stainless steel and titanium.

Matching Materials for Optimal Results

The material of the drill bit and the material of the sump pump must be compatible to achieve the best drilling outcomes. For example, if drilling into a cast iron sump pump, a cobalt alloy drill bit is recommended for its ability to resist wear and maintain sharpness. Conversely, a high-speed steel drill bit would be sufficient for drilling into a plastic sump pump housing.

Consideration of Drilling Performance

The characteristics of different drill bit materials also impact their performance. Hardness determines the bit’s ability to penetrate the material, while toughness influences its resistance to breakage. Wear resistance ensures the bit’s longevity and prevents excessive dulling. By understanding these characteristics, you can select a drill bit that meets the specific requirements of the sump pump material and drilling task.

Additional Factors to Consider

Apart from material compatibility, other factors may also influence drill bit selection. These include the bit diameter and shape, drill speed and feed rate, and cooling and lubrication techniques. By considering all these aspects, you can ensure precise drilling, proper hole placement, and optimal sump pump performance.

Cooling Techniques: A Vital Aspect of Drilling Success

In the realm of drilling, the need for cooling and lubrication cannot be overstated. These techniques play a crucial role in minimizing friction, preventing overheating, and extending the lifespan of your drill bit. Understanding and implementing effective cooling methods is essential for achieving optimal drilling performance and maximizing the longevity of your equipment.

Benefits of Cooling and Lubrication

- Reduced friction: Coolants and lubricants act as a barrier between the drill bit and the material being cut, reducing the friction generated during drilling. This reduction in friction translates into smoother drilling, less wear on the drill bit, and a longer tool life.

- Prevention of overheating: Heat is a major enemy of drill bits, as it can soften the cutting edges and reduce their effectiveness. Coolants and lubricants absorb heat generated during drilling, preventing the drill bit from overheating and prematurely failing.

- Extended drill bit life: By reducing friction and preventing overheating, cooling and lubrication techniques significantly extend the life of your drill bits. This translates into reduced downtime, cost savings, and increased productivity.

Choosing the Right Cooling Method

The choice of cooling method depends on the material being drilled, the drilling conditions, and the available resources. Some common cooling methods include:

- Dry drilling: This is the simplest and most common method, involving no coolants or lubricants. It is suitable for drilling soft materials such as wood and plastic.

- Flood cooling: This method involves submerging the drill bit in a coolant bath during drilling. It is effective for drilling hard materials such as metal and concrete.

- Mist cooling: This method sprays a fine mist of coolant onto the drill bit during drilling. It is a less messy option than flood cooling and is suitable for drilling materials of varying hardness.

Proper Application

Once you have selected the appropriate cooling method, it is important to apply it correctly. Follow these guidelines:

- Use a sufficient amount of coolant or lubricant: Ensure that the drill bit is adequately coated with the cooling agent.

- Apply coolant or lubricant before and during drilling: Begin applying the cooling agent before the drill bit makes contact with the material and continue applying it throughout the drilling process.

- Monitor coolant or lubricant levels: Regularly check the coolant or lubricant reservoir and replenish it as needed to maintain optimal cooling performance.

Optimized Hole Spacing and Arrangement: Ensuring Proper Sump Pump Function

Drilling holes for your sump pump is not just about creating passages for water to flow. Proper hole spacing and arrangement are crucial for the efficient and long-lasting operation of your sump pump system.

Distributing Weight Evenly

Sump pumps are typically installed in the lowest point of a basement or crawlspace to collect and pump out excess water. These pumps can be quite heavy, especially when filled with water. Optimizing hole spacing ensures that the weight of the sump pump and water is distributed evenly across the sump basin. This prevents the sump pump from sinking into the ground or becoming unstable, which can affect its performance and longevity.

Allowing for Proper Drainage

The arrangement of holes also plays a crucial role in allowing water to drain properly into the sump basin. Holes that are too close together can hinder the flow of water, causing it to pool around the sump pump and potentially overwhelm the pump. By spacing the holes appropriately, you create channels for water to flow freely into the basin, ensuring efficient drainage.

Preventing Water Pooling

Proper hole spacing also helps in preventing water pooling in the sump basin. Water that pools can corrode the sump pump and its components, shortening their lifespan. Additionally, stagnant water can become a breeding ground for mold and bacteria, posing health risks to occupants. By ensuring that the holes are arranged to promote proper drainage, you can minimize the risk of water pooling and its associated problems.

Optimizing hole spacing and arrangement for your sump pump installation is essential for its effectiveness, durability, and safety. By distributing weight evenly, allowing for proper drainage, and preventing water pooling, you can ensure that your sump pump operates at its best, keeping your basement or crawlspace dry and protected from water damage.