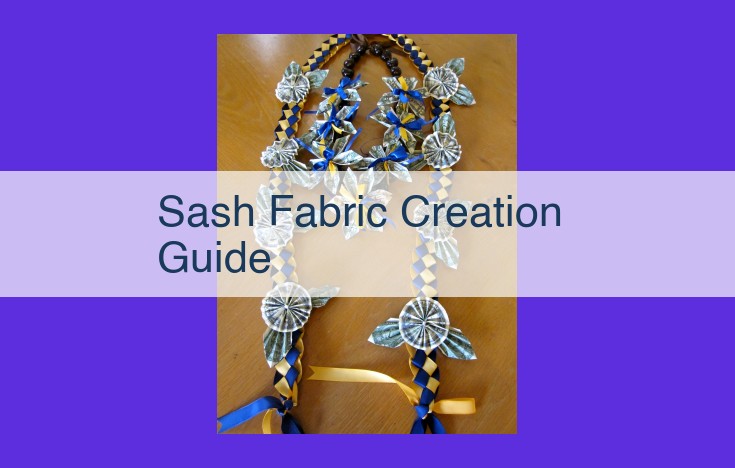

Master The Art Of Sash Creation: A Comprehensive Guide To Fabric, Fit, And Finish

This comprehensive guide empowers you to create stunning sashes. Explore fabric selection, pattern choices, and the crucial role of interfacing. Master precise fabric cutting, expert seaming, and zipper installation for a secure fit. Enhance your sash with elegant edge finishing, functional buttonholes, and stylish buttons. Finally, learn the art of ironing and pressing to achieve a polished look.

Fabric Selection for Sash-Making: A Journey Through Perfect Pairings

In the realm of sash-making, fabric selection takes center stage, setting the tone for your creation’s aesthetics and functionality. As you embark on this enchanting journey, let’s explore the world of fabrics, where each thread whispers a tale.

Delving into the Fabric Universe

Like a tapestry woven with diverse hues, the fabric kingdom offers a myriad of choices. Cottons, whispery and gentle, drape gracefully, while silks, with their luxurious sheen, exude elegance. Linens, with their earthy charm, add a touch of rusticity. Each fabric possesses a unique personality, its weight, drape, texture, and color pattern waiting to harmonize with your sash design.

Finding the Perfect Match

As you delve deeper, consider the weight of the fabric. Lightweight fabrics, like chiffons and organzas, float effortlessly, while heavier fabrics, such as brocades and velvets, provide substantial structure. The drape determines how the fabric falls, creating soft cascades or crisp folds.

Texture and Color: A Symphony of Senses

The texture of the fabric adds a tactile dimension, from the soft caress of suede to the intricate weave of damask. Color patterns, from vibrant solids to subtle prints, bring a dash of vibrancy or a touch of understated charm.

As you navigate the fabric wonderland, remember that the intended use of your sash will guide your choice. A sash for a formal occasion may call for luxurious fabrics like silk or velvet, while a casual sash for everyday wear might embrace the comfort of cotton or linen.

Fabric selection for sash-making is a symphony of art and practicality. By exploring different fabrics and their unique characteristics, you’ll find the perfect pairing to create a sash that reflects your style and becomes a cherished accessory for years to come. As you navigate the fabric realm, let your creativity soar, and may your sash-making journey be filled with beautiful discoveries!

Choosing the Right Pattern: The Cornerstone of Sash Creation

As you embark on your sash-making adventure, selecting the perfect pattern is crucial. A well-chosen pattern will not only complement your design but also ensure a comfortable fit and effortless construction.

When browsing patterns, consider the overall style and aesthetics of your sash. Do you envision a flowy bohemian vibe or a tailored, sophisticated look? Different patterns lend themselves to different aesthetics, so choose one that aligns with your desired outcome.

Fit is paramount. Measure yourself carefully, consult the pattern’s size chart, and select a pattern that corresponds to your measurements. An ill-fitting sash will hinder your enjoyment and diminish its visual appeal.

Finally, the pattern’s instructions should be clear, concise, and easy to follow. A well-written pattern will guide you through each step of construction with precision, ensuring that you create a sash you’re proud of. Take the time to read through the instructions before committing to a pattern.

Remember, selecting the right pattern is like laying the foundation for a successful sash-making project. Invest time and effort in this crucial step, and you’ll be rewarded with a beautiful and well-crafted creation that you’ll cherish for years to come.

Interfacing: The Foundation Layer of Your Sash

Interfacing is the unsung hero of any sash project. It’s the hidden support system that gives your sash structure, stability, and longevity. Understanding this crucial material is essential for creating a sash that will turn heads and withstand the test of time.

What is Interfacing?

Think of interfacing as the backbone of your fabric. It’s a woven or non-woven fabric that’s fused to the wrong side of your main fabric, providing additional strength, rigidity, and support. Without interfacing, your sash would be flimsy and easily lose its shape.

Types of Interfacing

Interfacings come in a wide range of types, each with its own unique properties. The most common types include:

- Fusible Interfacing: This type is heat-activated and can be easily ironed onto the fabric. It’s perfect for lightweight fabrics that need a bit of extra support.

- Sew-In Interfacing: This type is sewn onto the fabric, providing a stronger bond but requiring more time and effort. It’s ideal for heavier-weight fabrics that need maximum stability.

- Non-Woven Interfacing: This type is made of a needle-punched fiber web, providing a softer and more flexible support. It’s a good choice for fabrics that need a little more drape.

Selecting the Right Interfacing

The key to choosing the right interfacing is to consider the weight and drape of your fabric. A lightweight fabric, such as silk or chiffon, would require a lightweight interfacing like a fusible interfacing. A heavier fabric, such as cotton canvas or velvet, would need a heavier interfacing like a sew-in interfacing.

Remember, interfacing is the foundation of your sash. By carefully selecting and applying the right type of interfacing, you’ll ensure that your sash looks stunning and lasts for years to come.

Mastering Precise Fabric Cutting Techniques for Flawless Sashes

Embark on the sartorial journey of creating a stunning sash, where precision in fabric cutting lays the cornerstone for a flawless outcome. In this endeavor, three indispensable tools await you:

1. Scissors:

Wield the razor-sharp edges of your scissors to navigate the fabric’s delicate curves and intricate details. Choose scissors tailored specifically for fabric cutting, ensuring clean snips that prevent fraying.

2. Cutting Mats:

Elevate your cutting surface with a cutting mat. It protects your work surface from scratches while providing a stable and non-slip base for precise cutting. Opt for self-healing mats that seal cuts instantly, extending their lifespan.

3. Rotary Cutters:

Harness the power of a rotary cutter for long, straight cuts. Use a sharp blade and a comfortable handle to glide effortlessly through layers of fabric. Rotary cutters offer speed and accuracy, minimizing the risk of fabric distortion.

Tips for Precision Cutting:

- Measure Twice, Cut Once: Measure the fabric meticulously using a ruler or measuring tape. Mark the cutting lines clearly to avoid mistakes.

- Use Sharp Tools: Dull scissors and rotary blades will tear the fabric, compromising its integrity. Keep your tools sharp to ensure clean, precise cuts.

- Cut on a Flat Surface: A stable and level surface is crucial for accurate cutting. Ensure your cutting mat or table is flat and free of any bumps or distractions.

- Avoid Cutting on Bias: Cutting on a bias, or diagonally across the fabric grain, can stretch the fabric and distort its shape. Cut parallel to the fabric’s grain to maintain its integrity.

- Use Weights and Templates: For intricate cuts or repetitive shapes, consider using weights or templates to guide your cutting. This prevents the fabric from shifting and ensures consistent results.

Mastering these cutting techniques empowers you to create sashes with impeccable precision, laying the foundation for a captivating and well-crafted accessory.

Seaming for Strength and Precision: The Secret to a Sturdy Sash

Seaming is the heart of sash-making, the meticulous joining of fabric pieces that gives your sash its shape and durability. In this crucial step, it’s essential to select the appropriate sewing machine, thread, and seam allowance to ensure a perfect fit and lasting strength.

Mastering different seam types is key to creating a professional-looking sash. The plain seam is a classic choice, ensuring a secure and tidy connection. The French seam conceals raw edges within the seam allowance, creating a clean and elegant finish. For a more decorative touch, the flat-felled seam features a topstitched edge that adds visual interest and durability.

Finishing techniques play a vital role in enhancing the seam’s strength and longevity. Serging uses a specialized machine to create a stitched edge that prevents fraying. Binding involves encasing raw edges with a strip of fabric, providing a neat and durable finish. Facing conceals raw edges with a separate piece of fabric, creating a polished and professional look.

By carefully selecting the right materials, techniques, and finishes, you’ll create seams that not only hold your sash together but also add to its aesthetic appeal. Your sash will be a testament to your precision and attention to detail, ready to enhance your outfit with style and functionality.

Zipper Installation for Easy Closure: A Step-by-Step Guide

When it comes to crafting a sash that combines both style and functionality, zipper installation plays a crucial role. Zippers provide an easy and convenient way to open and close your sash, ensuring a snug fit and hassle-free dressing.

Choosing the Right Zipper

The first step in zipper installation is selecting the correct zipper type and length. Different zippers come in various sizes, materials, and colors, so it’s essential to choose one that complements your sash design. For most sashes, a dress zipper made of nylon or metal is a suitable choice.

Measuring and Cutting

Once you have your zipper, you need to measure the desired length for your sash. Cut the zipper to size, ensuring it’s not too short or too long. You also need to cut a small rectangle of fabric to serve as the zipper guard, which will prevent the zipper from rubbing against the skin.

Pinning and Sewing

Now, pin the zipper to the right side of your sash fabric, aligning the zipper teeth with the fabric edge. Begin sewing the zipper in place, using a zipper foot on your sewing machine. Start at one end and sew towards the other, ensuring even and secure stitches.

Installing the Zipper Guard

After sewing the zipper in place, it’s time to install the zipper guard. Pin the fabric rectangle over the zipper teeth, ensuring it covers the stitching and the ends of the zipper tape. Sew the zipper guard in place, using a small stitch length.

Finishing Touches

Once the zipper is installed, check if it operates smoothly. If there are any snags, carefully remove the zipper and adjust the stitching or zipper tape as needed. Finally, press the zipper area to ensure a neat and professional finish.

With the zipper securely installed, your sash now has an easy and functional closure mechanism. Whether you’re creating a formal or casual sash, a well-installed zipper will elevate its style and convenience.

Finishing Edges with Style and Durability: The Art of Crafting Polished Sashes

Your sash is almost complete, and now it’s time to refine its edges, giving it professionalism and longevity. In this crucial step, we’ll delve into the techniques of hemming, serging, binding, and facing—essential skills that will transform your sash into a masterpiece.

Hemming Techniques: Crisp and Clean

Hemming is an art form, adding a neat and tidy finish to your sash. Discover various hemming techniques, each with its own unique look and application. From simple machine-stitched hems to elegant hand-stitched rolled hems, find the one that best complements your sash’s design.

Serging: Preventing Fraying with Precision

Serging is a technique that uses a special machine to trim and overcast fabric edges simultaneously. This creates a strong, durable seam that prevents fraying and unraveling. Whether you prefer a 3-thread overlock stitch or a more elaborate 5-thread cover stitch, serging will ensure your sash withstands the test of time.

Binding: Enhancing Strength and Style

Binding is a method of encasing raw edges with a narrow strip of fabric, creating a clean and reinforced finish. This technique not only adds strength to your sash but also gives it a decorative touch. Experiment with different binding fabrics and colors to match your design.

Facing: Creating a Polished Inner Finish

Facing is the process of attaching a separate layer of fabric to the inside of your sash, concealing raw edges and providing stability. This technique is particularly useful for areas that receive extra wear and tear, such as buttonholes and zippers. By carefully matching the facing fabric to your sash, you can create a seamless and professional-looking finish.

Mastering the art of finishing edges is the key to creating a sash that exudes quality and craftsmanship. By exploring these techniques, you can elevate your sash to a new level of style and durability. Remember, attention to detail in this final step will make a world of difference in the overall appearance and longevity of your creation.

Creating Buttonholes for Functional and Decorative Enhancements

In the realm of sewing, buttonholes transform mere fabric into garments that can be adorned and fastened with ease. They not only serve a practical purpose but also add a touch of elegance and style. To achieve flawless buttonholes that enhance the beauty and functionality of your sash, understanding different buttonhole types and techniques is crucial.

Understanding Buttonhole Types

The world of buttonholes is not a one-size-fits-all scenario. Different fabrics and designs call for specific types of buttonholes.

- Straight Buttonholes: The most basic and versatile, these are ideal for lightweight fabrics like cotton and linen.

- Bound Buttonholes: As their name suggests, these buttonholes are bound with fabric, creating a durable and elegant finish. They are suitable for medium-weight fabrics like wool or denim.

- Piped Buttonholes: These buttonholes feature a small cord or piping inserted into the opening, adding a decorative touch to heavier fabrics like velvet or brocade.

Determining Size, Placement, and Stitch Settings

The perfect buttonhole is one that is neither too tight nor too loose, allowing the button to slide through smoothly. To determine the correct size, carefully measure the thickness of the button and add a bit of extra space for ease of use.

Placement is equally important. Mark the buttonhole’s location accurately, ensuring it is aligned for proper fastening and visual appeal.

As for the stitch settings, refer to your sewing machine manual for the recommended settings for your specific fabric and buttonhole type. Fine-tuning the tension and stitch length is essential for creating strong and secure buttonholes.

Executing Buttonholes with Precision

With the details sorted, it’s time to bring those buttonholes to life. Patience and a steady hand are key.

- Mark the Buttonhole: Use a fabric marker or tailor’s chalk to mark the buttonhole’s location and size.

- Stabilize the Fabric: Place interfacing behind the fabric to prevent stretching and ensure the buttonhole’s stability.

- Set the Machine: Choose the appropriate buttonhole foot and select the desired stitch settings.

- Sew the Buttonhole: Slowly and carefully guide the fabric through the machine, following the marked guidelines.

- Reinforce the Ends: Secure the ends of the buttonhole with a few stitches to prevent fraying.

Creating buttonholes adds not only functionality but also a touch of finesse to your garments. By mastering different buttonhole types and practicing precision, you can elevate your sewing projects to the next level.

Attaching Buttons: The Finishing Touch:

- Select buttons that complement your sash design. Learn how to attach buttons securely and professionally for both functionality and aesthetics.

Attaching Buttons: The Finishing Touch

The final step in crafting your exquisite sash is attaching the buttons. This intricate detail not only serves a functional purpose but also enhances the aesthetic appeal of your creation. Selecting the perfect buttons is paramount. Consider the design of your sash and choose buttons that complement its style and color scheme. High-quality buttons made from durable materials will ensure longevity and maintain their luster over time.

Once you have chosen your buttons, it’s time to attach them securely. There are various methods to choose from, each with its own advantages. Hand-sewing offers a classic and precise approach, while machine sewing provides speed and efficiency. Whichever method you choose, it’s essential to ensure a firm and even stitch.

For a professional finish, take the time to align the buttons precisely. They should be equidistant and parallel to each other. Use a ruler or measuring tape to create a symmetrical and visually pleasing arrangement.

Don’t forget to reinforce the buttons to prevent them from falling off. Double-stitching around the base of the button adds extra strength. You can also use buttonhole thread, which is specifically designed for durability.

Finally, ironing the sash around the buttons will set the threads and give the attachment a crisp and polished look. Use a pressing cloth to avoid scorching the fabric.

By meticulously following these steps, you’ll create a sash that is not only functional but also a true work of art. The buttons will serve as the finishing touch, adding both functionality and aesthetic charm to your handmade masterpiece.

Ironing and Pressing: Perfecting the Details

Ironing and pressing are essential steps in the sash-making process that can elevate your creation from ordinary to extraordinary. By carefully ironing and pressing each component of your sash, you can achieve crisp edges, remove wrinkles, and enhance the overall appearance of your finished product.

Understanding the Importance

Ironing and pressing serve multiple purposes in sash-making. They:

- Flatten seams and remove wrinkles: Pressing seams flat reinforces them, prevents puckering, and gives your sash a professional finish.

- Sharpen edges: Pressing along the edges of your sash creates crisp, clean lines that accentuate the design and make the sash look more tailored.

- Set interfacing: Proper pressing helps to set the interfacing in place, ensuring that it provides the necessary stability and structure to your sash.

Techniques and Tools

The key to successful ironing and pressing lies in using the right techniques and tools.

- Iron or Pressing Machine: Opt for an iron with steam capabilities to effectively remove wrinkles and set seams. Alternatively, you can use a professional pressing machine for larger-scale projects.

- Ironing Board: A well-padded ironing board provides a stable surface for pressing. Choose one that is large enough to accommodate your sash comfortably.

- Pressing Cloth: A press cloth acts as a barrier between your sash and the iron, preventing direct heat exposure and potential damage to delicate fabrics.

Settings and Tips

- Temperature: Adjust the iron’s temperature according to the fabric type of your sash. Use a lower temperature for delicate fabrics like silk or satin, and a higher temperature for heavier fabrics like canvas or denim.

- Steam: Use steam as it helps to moisten and relax the fibers, making them more pliable and easier to iron.

- Pressure: Apply firm but gentle pressure on the iron or pressing machine to avoid crushing the fabric.

- Ironing Direction: Iron with the grain of the fabric to prevent distortion and maintain its original shape.

Ironing and pressing are crucial steps in the sash-making process that can transform your creation into a polished and professional-looking accessory. By understanding the importance, techniques, and tools involved, you can master the art of ironing and pressing and elevate your sash to the next level.