Comprehensive Guide To Tap And Die Sizing For Precise Threading

- Introduction: Taps and dies are crucial for creating precise threads, necessitating their accurate sizing.

- Factors to Consider: Tap and die types, thread size, pitch, material, lubrication, and safety precautions must be carefully considered.

- Details: The guide covers tap drill size, die size, thread tolerance, class, form, material considerations, cutting fluid, and holding tools, providing a comprehensive understanding for successful threading operations.

The Importance of Precise Tap and Die Sizing for Faultless Threading

In the realm of engineering and manufacturing, achieving perfect threads is paramount. This precision is accomplished through the skillful use of taps and dies, which create intricate grooves and ridges on metal surfaces for bolts and nuts to engage. The accurate sizing of taps and dies is not merely a matter of aesthetics; it is the foundation for strong, secure, and interchangeable threaded connections.

Properly sized taps and dies ensure that:

- Threads align seamlessly, allowing for effortless assembly and disassembly.

- Threaded components fit snugly, preventing loosening or vibration-induced failures.

- Standard thread sizes can be used throughout a project or across multiple projects, ensuring compatibility and interchangeability.

In essence, the precise sizing of taps and dies is not just a technical requirement but a cornerstone of safety, reliability, and efficiency in threaded connections.

Types of Taps: A Guide to Their Functions and Applications

In the realm of metalworking, taps reign supreme as indispensable tools for creating precision threads. They come in a diverse array of types, each tailored to specific tasks and applications. Understanding these different taps is crucial for ensuring successful threading operations.

Hand Taps: The Manual Workhorses

Hand taps are the go-to choice for manual threading. They are characterized by their square shank, which is designed to be held in a tap wrench. Hand taps are available in a range of sizes and thread pitches, allowing for versatility in applications. They excel in situations where precision is paramount, such as creating threads in delicate components.

Machine Taps: Speed and Efficiency

Machine taps are designed for use in machine-threading operations. Unlike hand taps, they feature a round shank that fits into a tap holder. This design enables higher tapping speeds and automated threading, making them ideal for high-volume production environments. Machine taps are known for their durability and consistency.

Thread-Forming Taps: No Cutting Required

Thread-forming taps take a unique approach to creating threads. Instead of cutting material like traditional taps, they cold-form threads by displacing the material in the workpiece. This eliminates the need for chip removal and results in stronger, more durable threads. Thread-forming taps are commonly used in softer materials, such as aluminum and plastics.

Selecting the Right Tap

Choosing the appropriate tap type is key to achieving optimal results. Consider the following factors:

- Application: Determine whether manual or machine threading is required.

- Material: The tap material should be harder than the workpiece material.

- Thread size and pitch: Ensure the tap matches the desired thread specifications.

- Lubrication: Proper lubrication reduces friction and extends tap life.

Factors to Consider When Choosing the Perfect Tap for Your Threading Needs

When embarking on any threading operation, selecting the most suitable tap is paramount to achieving precise and successful results. Several key factors must be carefully evaluated to ensure an optimal tapping experience.

1. Thread Size and Pitch:

The size and pitch of the thread are fundamental considerations. Taps are available in a wide range of sizes, measured in inches or millimeters. The pitch, on the other hand, refers to the number of threads per inch or millimeter. Determining the exact thread size and pitch is crucial to ensure the tap creates the correct thread form on the workpiece.

2. Material Compatibility:

Choosing a tap material that is well-matched to the workpiece material is essential. Taps can be made from various materials, including high-speed steel, carbide, and cobalt. Each material offers unique properties and is best suited for specific workpiece materials. For instance, high-speed steel taps are versatile and economical, while carbide taps are ideal for hard materials like stainless steel.

3. Lubrication Requirements:

Tapping operations require proper lubrication to minimize friction, heat, and tool wear. Choosing the right type of cutting fluid is crucial. Soluble oil, tapping fluid, and dry lubricants serve this purpose. The specific lubrication requirements depend on the tap material, workpiece material, and threading conditions.

4. Tap Type:

Various tap types are available, each designed for specific applications. Hand taps are ideal for manual tapping operations, while machine taps are used in conjunction with tapping machines. Thread-forming taps create threads by plastically deforming the workpiece material, eliminating the need for pre-drilling. Selecting the appropriate tap type ensures efficient and accurate threading.

By thoughtfully considering these factors, you can ensure the selection of the most suitable tap for your threading project. This meticulous approach will result in precise threads, enhanced productivity, and reduced tool wear, ultimately leading to a successful and satisfactory threading experience.

Types of Dies: An Overview for Precision Threading

In the realm of threading operations, dies play a crucial role in shaping external threads on cylindrical workpieces. Understanding the different types of dies available empowers machinists with the knowledge to select the most appropriate tool for their specific needs.

Round Dies: The Versatile Choice

Round dies are the most common type of dies, characterized by their cylindrical shape and internal threading. They are typically used for general-purpose threading on a variety of materials. Round dies are available in a wide range of sizes and thread pitches, catering to a diverse range of applications.

Split Dies: For Tight Spaces and Quick Changes

Split dies consist of two halves that are held together by a screw. This design allows for quick and easy changes between different thread sizes and pitches. Split dies are particularly useful in confined spaces or when frequent thread changes are required. Their adjustability also allows for minor thread corrections.

Thread-Rolling Dies: Enhancing Strength and Precision

Thread-rolling dies employ a different technique to form threads. Instead of cutting the material, they cold-form the threads by pressing them into the workpiece. This process results in stronger, more precise threads with improved fatigue resistance. Thread-rolling dies are commonly used in high-volume production environments where precision and durability are paramount.

By comprehending the unique characteristics of each die type, machinists can make informed decisions based on the specific requirements of their projects. Whether it’s versatility, quick adaptability, or superior strength, the choice of die will significantly impact the quality and efficiency of any threading operation.

**Factors in Die Selection: Fine-Tuning Threading Precision**

Just as with taps, selecting the right die is crucial for ensuring precise and successful threading operations. Several key factors come into play when choosing the appropriate die:

**Thread Size and Pitch:**

The thread size and pitch dictate the size and shape of the threads to be cut. The die must match these dimensions exactly to create a clean, well-fitting thread. Using an incorrect die size or pitch can result in substandard threads that fail to meet specifications.

**Material Compatibility:**

The material of the die directly affects its durability and performance. Different materials are suited for various workpiece materials. For instance, carbon steel dies are suitable for general-purpose threading, while high-speed steel dies offer increased hardness and durability for tough materials.

**Lubrication:**

Lubrication plays a vital role in reducing friction and extending the life of the die. Applying a suitable cutting fluid to the die’s threads helps ensure smooth cutting and prevents premature wear. Choosing the right lubricant depends on the materials being cut and the severity of the threading operation.

Thread Size and Pitch: The Cornerstones of Precise Threading

In the realm of precision machining, thread size and pitch play crucial roles in ensuring the success of threading operations. Understanding their significance and the intricate relationship between them is paramount for achieving optimal results.

Thread size refers to the diameter of the screw or bolt, measured in millimeters (mm) or inches (in). It determines the thickness of the threaded component and the size of the mating part.

Thread pitch, on the other hand, denotes the distance between two adjacent thread peaks or valleys, expressed in threads per inch (TPI) or millimeters per thread (mm/th). A higher pitch results in fewer threads per inch, while a lower pitch yields more threads per inch.

The relationship between thread size and pitch is inversely proportional. This means that as the thread size increases, the pitch decreases, and vice versa. This relationship ensures compatibility between mating parts, allowing for tight and secure connections.

Accurate measurements of thread size and pitch are vital for proper fit and functionality. Mismatched threads can lead to cross-threading, damage, or failure, compromising the integrity of the assembly. Therefore, it is imperative to use precise measuring tools and adhere to industry standards when determining thread specifications.

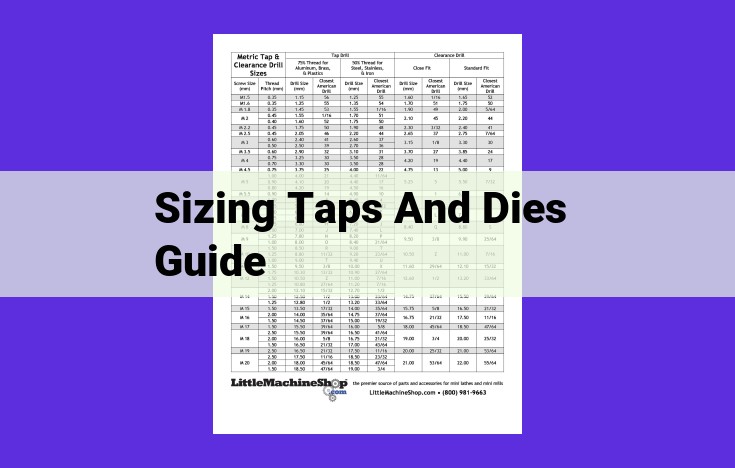

Tap Drill Size:

- The significance of using the correct drill size for tapping and the guidelines for determining the appropriate size based on thread size and pitch.

Tap Drill Size: The Key to Successful Threading

In the world of precision machining, the right tools make all the difference. One crucial factor in successful tapping is using the correct tap drill size. Why does it matter? Imagine trying to fit a square peg into a round hole. If the hole is too small, you’ll struggle to insert the peg. Similarly, if the hole is too large, the peg will wobble and create a loose fit.

The same principle applies to tapping. The tap drill size determines the diameter of the hole you create before tapping. Too small a hole can hinder the tap’s progress and potentially break it. Too large a hole, and the threads will be weak and susceptible to failure.

Determining the Tap Drill Size

The tap drill size is directly related to thread size and pitch. Thread size refers to the nominal diameter of the thread, while pitch is the distance between two consecutive thread crests. Using a formula or a reference table, you can determine the recommended tap drill size for a specific thread size and pitch.

For example, if you want to tap a 1/4-inch UNC thread with a pitch of 20 threads per inch, the recommended tap drill size is 13/64 inch. This will give you the optimal hole diameter for the tap to engage and create the desired threads.

Why Tap Drill Size Matters

Using the correct tap drill size ensures:

- Proper thread engagement: The tap can fully engage with the workpiece, ensuring a strong and secure thread.

- Reduced tap wear: The correct hole size minimizes friction and extends tap life.

- Accurate thread pitch: The tap drill size ensures that the threads are spaced correctly for optimal strength.

- Avoidance of tap breakage: The appropriate hole size prevents the tap from being subjected to excessive force and reduces the risk of breakage.

Choosing the correct tap drill size is a fundamental step in precision tapping. Understanding the relationship between thread size, pitch, and tap drill size will empower you to create strong, durable threads that meet your specifications. By following the guidelines outlined in this article, you can ensure the success of your tapping operations and elevate your machining skills to the next level.

Determining the Appropriate Die Size for Optimal Threading

Producing precise threads requires meticulous attention to detail, including the selection of the correct die size. This guide will delve into the factors that influence die size determination, empowering you with the knowledge to achieve optimal performance in your threading operations.

Thread Size and Pitch: A Foundation for Accuracy

The thread size and pitch, two integral thread characteristics, play a pivotal role in determining the appropriate die size. Thread size refers to the diameter of the threaded section, while pitch denotes the distance between adjacent thread peaks. Accurate measurements and correspondence between the die size and thread size are essential for ensuring proper engagement and thread quality.

Material and Lubrication: Considerations for Success

The material used in your workpiece and the type of cutting fluid employed can also influence die size selection. Different materials exhibit varying levels of hardness and machinability, requiring appropriate dies with suitable cutting geometry and wear resistance. Lubrication plays a vital role in reducing friction and preventing tool damage, and the type of cutting fluid (such as oil or coolant) should be compatible with the material and die material.

Die Types and Their Influence on Size

Various die types, each designed for specific applications, impact die size considerations. Round dies, often used for general-purpose threading, offer versatility and ease of use. Split dies, available in two halves, provide greater accuracy and are suitable for high-volume production. Thread-rolling dies utilize a cold forming process, resulting in high-strength threads.

Calculating Die Size: A Step-by-Step Approach

Determining the die size involves calculating the outside diameter (OD) of the thread to be produced. The formula to derive OD is:

OD = Thread Size + (2 x Depth of Thread)

Once you have calculated the OD, the corresponding die size can be deducted by subtracting the thread size from the OD:

Die Size = OD - Thread Size

Additional Factors to Consider

Beyond thread size, pitch, material, and lubrication, other factors can influence die size selection:

- Thread Tolerance: Specifies the acceptable variation in thread dimensions.

- Thread Class: Defines the precision and fit of the thread.

- Thread Form: The shape of the thread profile, such as Unified National Coarse (UNC) or Unified National Fine (UNF).

Proper die size selection is indispensable for successful threading operations. By considering the interplay of thread size and pitch, material and lubrication, die type, and additional factors, you can make informed decisions that enhance thread quality, productivity, and safety.

Thread Tolerance: Ensuring Precise and Interchangeable Threads

When it comes to threading operations, precision is paramount. Ensuring that the threads created are accurate and consistent is crucial for achieving a successful result. Thread tolerance plays a vital role in this equation, as it defines the permissible variations in the dimensions of the threads.

Understanding Thread Tolerance

Thread tolerance refers to the allowable deviations in thread size, pitch, and form from the specified nominal dimensions. It is expressed in grades, with each grade representing a different level of precision.

- Fine: Indicating the highest level of precision, fine tolerance threads are used in critical applications where exact fit and interchangeability are essential, such as aerospace components.

- Medium: Offering a balance between precision and cost, medium tolerance threads are commonly used in general industrial applications where interchangeability is important but not as demanding as in fine tolerance applications.

- Coarse: Providing the lowest level of precision, coarse tolerance threads are employed in non-critical applications where loose fit and easy assembly are more important than precise dimensions.

Implications for Interchangeable Threads

The grade of thread tolerance directly impacts the ability to interchange threaded components. Threads with tighter tolerances, such as fine tolerance, will have a higher degree of interchangeability than threads with looser tolerances, such as coarse tolerance.

This is because tighter tolerances ensure that the threads on different components match more precisely, allowing for easier assembly and reducing the risk of misalignment or binding. Conversely, looser tolerances may result in variations in thread dimensions that can make component interchangeability more challenging.

Optimizing Thread Tolerance

Selecting the appropriate thread tolerance grade is essential for achieving the desired level of precision and interchangeability. Factors to consider include:

- The intended application and the level of precision required

- The materials being used and their machining characteristics

- The manufacturing capabilities and equipment available

By carefully considering these factors, you can optimize thread tolerance to ensure the production of precise and interchangeable threaded components, enhancing the overall quality and reliability of your products.

Mastering Threading Perfection: A Guide to Taps, Dies, and Precision

The Art of Sizing Taps and Dies

Precision threading is paramount for successful mechanical operations. Mismatched taps and dies can compromise the integrity of your threads, creating a host of problems. This guide will delve into the world of taps and dies, empowering you with the knowledge to size these essential tools for flawless threading.

Taps: The Threading Architects

Taps are cutting tools used to create internal threads on workpieces. They come in various types, each suited for specific applications. Hand taps, as their name suggests, are manually operated, while machine taps are designed for use in tapping machines. Thread-forming taps, on the other hand, shape threads without removing material.

Dies: The Threading Sculptors

Dies are external threading tools that cut male threads on workpieces. Round dies create threads by rotating the workpiece, while split dies offer greater precision and durability. Thread-rolling dies use pressure to form threads, resulting in stronger and more accurate threads.

Thread Size and Pitch: The Threading Blueprint

Thread size and pitch are crucial parameters that determine the dimensions and spacing of threads. Accurate measurements are essential to ensure proper engagement between mating components.

Tap Drill Size: The Precursor to Tapping

The tap drill size, which determines the diameter of the hole that precedes tapping, plays a significant role in ensuring successful threading. Specific guidelines exist for determining the appropriate drill size based on thread size and pitch.

Die Size: The Template for Male Threads

Similar to tap drill size, die size must align with thread size and pitch. Proper sizing minimizes material removal and ensures optimal thread formation.

Thread Tolerance: The Precision Standard

Thread tolerance defines the allowable variations in thread dimensions. Understanding thread tolerance grades is essential for achieving precise and interchangeable threads.

Thread Class: The Threading Hierarchy

Thread classes specify the level of precision and application suitability for a given thread. Different thread classes have varying tolerance grades and specifications.

Thread Form: The Threading Profile

The thread form refers to the shape of the thread’s profile. Common thread forms include Unified National Coarse (UNC), Unified National Fine (UNF), and Metric threads. Choosing the appropriate thread form depends on factors such as strength, durability, and industry standards.

Material Considerations: The Threading Substance

The material of taps and dies must be compatible with the workpiece material to ensure optimal performance. High-speed steel, cobalt, and carbide are common choices for taps and dies, each offering unique advantages and applications.

Cutting Fluid: The Threading Lubricant

Cutting fluid plays a vital role in threading operations, providing lubrication and cooling. Selecting the appropriate cutting fluid enhances thread quality, extends tool life, and improves safety.

Holding Tool: The Threading Grip

Tap holders and die holders securely grip taps and dies during threading operations, ensuring stability and precision. Proper selection of holding tools is essential for successful threading.

Safety Precautions: The Threading Imperative

Working with taps and dies requires adherence to strict safety precautions. Proper eye and hand protection are essential, while avoiding overtightening ensures tool safety and workpiece integrity.

Thread Form:

- Discussion of common thread forms, their characteristics, and the factors influencing their selection for specific applications.

Thread Form: A Critical Aspect in Threading Operations

Selecting the appropriate thread form is crucial for ensuring precise and functional threading operations. Thread forms vary in their characteristics and applications, influencing their suitability for specific projects.

Common thread forms include:

- Unified National Fine (UNF): A widely used thread form with precise threads and a high thread density.

- Unified National Coarse (UNC): A coarser thread form compared to UNF, often used for less critical applications.

- Acme Threads:** Characterized by a trapezoidal shape, these threads provide high strength and resistance to axial forces.

- Buttress Threads:** Designed for one-directional loads, buttress threads feature an asymmetrical profile.

- Square Threads:** Known for their high friction and load-bearing capacity, square threads are commonly used in precision applications.

Factors to consider when choosing a thread form include:

- Application load: Different thread forms offer varying load capacities, so it’s essential to select a form that can handle the expected forces.

- Material: The material of the workpiece and the desired strength of the threads influence the thread form selection.

- Thread pitch: The thread pitch, or the distance between threads, affects the strength and fit of the threads.

- Compatibility: When mating threaded components, it’s crucial to ensure compatibility between the thread forms.

By selecting the appropriate thread form, you can achieve precise, durable, and functional threaded connections.

The Crucial Considerations of Choosing the Right Materials for Taps and Dies

In the realm of tapping and threading operations, the choice of materials for your taps and dies holds immense significance. The optimal performance of these tools hinges on their ability to glide effortlessly through the workpiece material, producing precise and enduring threads.

Understanding the Workpiece Material

The nature of the workpiece material you’ll be working with is paramount in material selection. Various materials, such as metals (e.g., steel, aluminum) or plastics, demand different cutting tool materials that can handle their unique properties.

Heat Resistance and Durability

When it comes to high-temperature scenarios or demanding applications, look for heat-resistant materials. These materials can withstand the intense friction and heat generated during the threading process, ensuring exceptional durability.

Hardness and Strength

For hard and sturdy workpieces, such as hardened steel, opting for taps and dies made of high-carbon steel or carbide is essential. These materials possess the necessary hardness and strength to penetrate the tough material and create clean, accurate threads.

Compatibility with Lubricants

Choosing a material that is compatible with the cutting fluid you intend to use is crucial. This ensures optimal lubrication, reduces friction, and enhances tool life.

Balancing Material Trade-Offs

Striking a balance between the desired properties is often necessary. For instance, while carbide provides exceptional hardness, it can be more brittle than high-carbon steel. Consider the specific application requirements and material constraints to make an informed choice.

Additional Considerations

Furthermore, factors such as corrosion resistance and magnetic properties may also influence material selection. Choose materials that can withstand the operating environment and meet the specific needs of your application.

In conclusion, the choice of materials for taps and dies is a critical aspect of successful threading operations. By carefully considering the workpiece material, desired performance, and compatibility with cutting fluids, you can ensure the selection of tools that will deliver exceptional results time and again.

The Cutting Edge: Understanding Cutting Fluids for Precision Threading

When it comes to creating precise threads, using the right cutting fluid is as crucial as selecting the perfect tap or die. These specialized fluids play a vital role in ensuring smooth cutting, reducing friction, and enhancing the overall quality of your threaded components.

Benefits of Cutting Fluids

Cutting fluids offer a myriad of benefits that make them indispensable in any threading operation:

- Reduced friction: Cutting fluids lubricate the contact surfaces between the tap or die and the workpiece, minimizing friction and preventing galling or seizing.

- Improved cutting performance: The lubricity of cutting fluids aids in chip removal, resulting in cleaner threads and extended tool life.

- Heat dissipation: Cutting fluids absorb heat generated during the threading process, preventing thermal damage to the workpiece or the tool.

- Corrosion protection: Many cutting fluids contain additives that prevent corrosion on the workpiece and the tools, prolonging their lifespan.

Types of Cutting Fluids

The choice of cutting fluid depends on various factors, including the workpiece material, the threading operation, and the desired finish. Common types of cutting fluids include:

- Mineral oils: These general-purpose fluids are widely used in threading ferrous metals.

- Synthetic oils: Designed for high-speed operations, synthetic fluids provide excellent lubrication and cooling.

- Water-soluble oils: Emulsifiable in water, these fluids are ideal for ferrous metals, particularly those sensitive to corrosion.

- Chemical fluids: Tailored for specific materials like stainless steel, chemical fluids prevent staining and promote thread quality.

Safety Precautions

While cutting fluids enhance threading efficiency, it’s crucial to adhere to proper safety precautions:

- Proper ventilation: Ensure adequate ventilation to avoid inhaling mist or fumes.

- Eye protection: Wear safety goggles to protect your eyes from splashes.

- Hand protection: Use gloves to prevent skin irritation from contact with the fluid.

- Avoid overtightening: Excessive force can damage both the tool and the workpiece.

- Follow manufacturer’s guidelines: Always consult the safety data sheet (SDS) and operating manuals for specific handling and disposal instructions.

Holding Tools for Precise Threading

In the world of threading operations, achieving precision and efficiency relies heavily on the tools you use. Among these tools, holding tools play a crucial role in securing and aligning taps and dies, ensuring successful and reliable threading operations.

Types of Tap Holders and Die Holders:

There are various types of tap holders and die holders available, each designed to accommodate different tapping and threading needs.

- Tap Holders: These holders provide a firm grip on taps, allowing for precise alignment and controlled tapping. They come in different sizes and shapes, such as hexagonal, square, and cylindrical, to fit various taps.

- Die Holders: Similar to tap holders, these tools hold and secure dies in place. They ensure accurate positioning and prevent the dies from slipping or vibrating, resulting in clean and uniform threads.

Importance of Holding Tools:

Using the appropriate holding tools offers several advantages:

- Security: Holding tools prevent taps and dies from spinning or falling out, ensuring operator safety.

- Accuracy: They provide precise alignment, minimizing the risk of cross-threading or damaged threads.

- Efficiency: Securely held taps and dies reduce chatter and vibration, allowing for faster and smoother threading operations.

- Consistency: With proper holding tools, you can maintain consistent thread quality, reduce rework, and improve productivity.

Choosing the Right Holding Tool:

Selecting the right holding tool depends on several factors:

- Tap or Die Size: Ensure the holder fits securely around the tap or die, providing adequate support and stability.

- Application: Consider the type of threading operation and the workpiece material. Different holding tools may be suitable for hand threading, machine threading, or specialized applications.

- Compatibility: The holder should be compatible with the tapping machine or die stock you are using.

By choosing the appropriate holding tool and using it correctly, you can enhance the precision, efficiency, and safety of your threading operations.

Safety First: Essential Precautions for Taps and Dies

When venturing into the world of taps and dies, safety should always take precedence. These tools may seem innocuous, but they can wield significant force and pose potential hazards. To ensure a safe and successful threading operation, follow these essential safety guidelines:

-

Don Eye Protection: Just as you don a helmet before entering a construction zone, eye protection is paramount when working with taps and dies. Metal chips and shavings can fly at high velocities, so safeguard your eyes with goggles or a face shield.

-

Protect Your Hands: Gloves are your hands’ armor against sharp edges and potentially hot tools. Wear sturdy gloves to prevent cuts and burns, ensuring your hands remain poised and pain-free.

-

Securely Grip the Tool: A firm grip is crucial for controlling the tool and preventing accidents. Use tap and die holders specifically designed to provide secure and comfortable handling. Never attempt to hold the tool barehanded, as it can slip and cause injury.

-

Avoid Overtightening: Patience is a virtue, especially when it comes to threading. Forcing the tap or die into the workpiece can result in damage to the threads or even breakage. Gently turn the tool, applying even pressure to achieve the desired results.

Remember, safety is not a suggestion but a necessity. By adhering to these precautions, you minimize risks, protect your well-being, and ensure a smooth and efficient threading experience.