Surge Tanks: Mitigating Pressure Surges And Protecting Hydraulic Systems

Surge tanks play a crucial role in hydraulic systems by preventing pressure surges and protecting equipment from water hammer. Strategically placed along pipelines and near pumps, they effectively mitigate pressure variations. Open, closed, and combined surge tanks offer distinct functions based on their capacity, diameter, flow rate, and pump characteristics. By optimizing their design, surge tanks enhance system reliability by reducing noise, preventing water hammer, and safeguarding equipment. Despite potential drawbacks related to cost and limitations, surge tanks are widely used in various industries, including water supply systems, hydroelectric power plants, pipelines, and industrial processes.

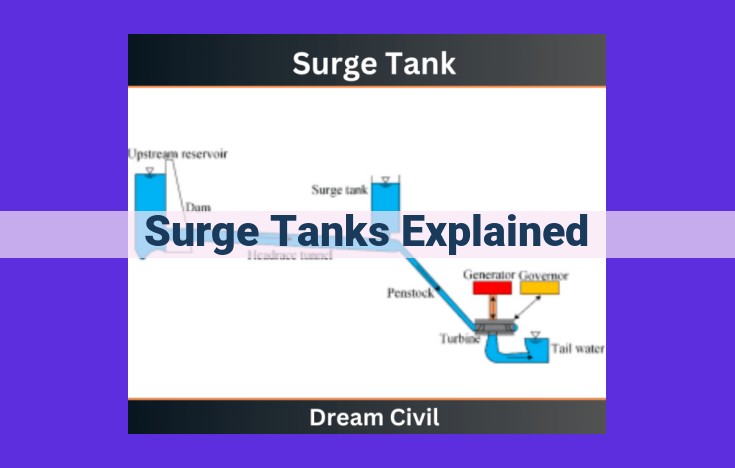

Understanding Surge Tanks: Guardians of Hydraulic Systems

In the intricate world of hydraulic systems, surge tanks emerge as unsung heroes, safeguarding equipment from the perils of pressure surges. These remarkable vessels play a crucial role in preventing the destructive force of water hammer, ensuring the smooth and efficient operation of hydraulic systems.

Surge Tanks: The Pressure Tamers

Surge tanks are expertly positioned along pipelines and near pumps, acting as buffers against sudden pressure fluctuations. When water flow is abruptly halted or altered, these tanks absorb the resulting pressure surges, preventing them from wreaking havoc downstream. By absorbing excess pressure, surge tanks protect pumps, valves, and other equipment from potential damage.

Types of Surge Tanks: Function and Form

Surge tanks come in various forms, each tailored to specific system requirements. Open surge tanks, with their unobstructed connection to the atmosphere, dissipate pressure by allowing water to flow in or out. Closed surge tanks, sealed at the top, utilize the elasticity of air to cushion pressure variations. Combined surge tanks ingeniously blend the features of open and closed tanks, providing flexibility and enhanced pressure control.

Optimizing Surge Tank Design: A Balancing Act

The design of surge tanks is a delicate dance between several factors. Their capacity, diameter, and flow rate must be carefully calibrated to match the characteristics of the pump and pipeline. By meticulously considering these parameters, engineers ensure that surge tanks effectively mitigate pressure fluctuations, preventing costly equipment failures.

The Benefits of Surge Tanks: Unlocking System Reliability

Surge tanks provide a multitude of benefits that enhance the reliability and efficiency of hydraulic systems. They prevent water hammer, which can cause catastrophic pipe bursts. Additionally, they reduce noise generated by pressure surges, creating a more pleasant work environment. By protecting equipment from damage, surge tanks minimize downtime and maintenance costs, ensuring the longevity of hydraulic systems.

Potential Drawbacks: Weighing the Costs

While surge tanks offer a wealth of advantages, they also come with potential drawbacks. Their cost can be a significant consideration, particularly for large-scale systems. Additionally, their size may require ample space, which can be a limitation in cramped environments. Cavitation, the formation of vapor bubbles due to pressure drops, can also occur within surge tanks, potentially reducing their effectiveness.

Diverse Applications: Where Surge Tanks Shine

Surge tanks find their place in a diverse array of industries, wherever hydraulic systems are employed. From water supply systems to hydroelectric power plants, from pipelines to industrial processes, surge tanks perform their vital role in maintaining system stability and protecting valuable equipment.

Surge tanks, the unsung heroes of hydraulic systems, play an indispensable role in preventing pressure surges and safeguarding equipment. By understanding their purpose, strategic placement, types, design considerations, benefits, and drawbacks, we gain a deeper appreciation of these guardians of hydraulic systems. Whether in the vast expanse of water pipelines or the intricate world of industrial processes, surge tanks ensure the smooth and efficient operation of hydraulic systems, underpinning our modern infrastructure and technological advancements.

Strategic Placement of Surge Tanks

The optimal placement of surge tanks in hydraulic systems is crucial for their effective operation in mitigating pressure variations. Here are key considerations for strategic placement:

Along Pipelines:

Surge tanks are typically positioned at points along pipelines where there is a significant change in elevation, flow direction, or pipe diameter. These locations experience the most pronounced pressure fluctuations, making surge tanks essential for absorbing and releasing pressure.

Near Pumps:

Pumps are a primary source of pressure surges in hydraulic systems. Therefore, surge tanks are often installed close to pumps, where they can immediately buffer the pressure fluctuations caused by pump operation. This helps prevent water hammer and protect downstream equipment from damage.

Multiple Surge Tanks in Series:

In long pipelines with severe pressure variations, it may be necessary to install multiple surge tanks in series. This arrangement allows for a staged reduction in pressure surges, ensuring more effective mitigation and improved system reliability.

Considerations for Effective Placement:

When selecting the precise locations for surge tanks, engineers consider factors such as:

- Pipe layout and topography: The position of surge tanks should minimize potential pressure transients.

- Flow rates and pump characteristics: The surge tank’s capacity and design must accommodate the specific flow conditions.

- System operating pressure: The tank’s pressure rating should exceed the maximum expected operating pressure.

- Accessibility and maintenance: The location should allow for easy inspection, maintenance, and repairs.

By carefully considering these aspects, engineers can optimize the placement of surge tanks to ensure their effectiveness in mitigating pressure variations and safeguarding hydraulic systems from the damaging effects of water hammer.

Types of Surge Tanks: Characteristics and Functions

In the realm of fluid dynamics, surge tanks emerge as crucial components in hydraulic systems, safeguarding equipment and ensuring system stability. Their primary function lies in mitigating pressure surges and preventing water hammer, the destructive force that can arise from sudden changes in flow velocity.

Open Surge Tanks: Simplicity and Efficiency

Open surge tanks rank among the most straightforward types, characterized by their open connection to the atmosphere. This design offers several advantages:

- Low cost and ease of construction: Their simplicity makes them economical to build and install.

- Rapid pressure absorption and release: Open tanks can readily absorb and release pressure by adjusting their water level, providing swift response to system fluctuations.

- Minimal head loss: The open design minimizes head loss, ensuring efficient fluid flow and system performance.

Closed Surge Tanks: Pressurized Protection

Closed surge tanks, unlike their open counterparts, remain sealed at the top. This pressurized environment offers unique benefits:

- Higher pressure capacity: Closed tanks can withstand much higher pressures than open tanks, making them suitable for high-head systems.

- Improved surge damping: The enclosed air cushion provides superior cushioning against pressure surges, effectively dampening vibrations and protecting equipment.

- Prevents cavitation: The pressurized interior eliminates the risk of cavitation, a phenomenon that can harm pumps and other system components.

Combined Surge Tanks: Versatility and Enhanced Performance

Combined surge tanks ingeniously combine features of both open and closed tanks:

- Optimal pressure control: They provide a balance between pressure surge mitigation and system efficiency.

- Customized design: Combined tanks can be tailored to meet specific system requirements by adjusting the ratio of open to closed volume.

- Wide applications: Their versatility makes them suitable for various hydraulic systems, from water supply networks to hydroelectric power plants.

Optimizing Surge Tank Design: Key Considerations

Delving into the Design Parameters

In crafting an effective surge tank design, a myriad of factors demand meticulous attention. One such consideration is capacity. This aspect determines the tank’s ability to accommodate the potential volume of water displaced during sudden pressure surges. A precisely sized surge tank ensures adequate protection against water hammer and safeguards system integrity.

Diameter: Striking a Balance

The surge tank’s diameter plays a crucial role in optimizing design. A wider diameter facilitates a more significant volume and reduced flow velocity within the tank, minimizing pressure fluctuations. However, it is essential to strike a balance, as an excessively large diameter can lead to excessive costs and space constraints.

Flow Rate: Understanding the System’s Dynamics

The flow rate through the system profoundly influences surge tank design. Fluctuations in flow rate can trigger pressure surges, necessitating a surge tank capable of mitigating these variations. Careful consideration of flow rates ensures the tank’s ability to effectively absorb and release water, maintaining a stable pressure balance.

Pump Characteristics: Matching Performance Parameters

The characteristics of the pumps within the system hold paramount importance in surge tank design. The pump’s capacity, head, and speed dictate the magnitude and duration of pressure surges. Designing a surge tank in harmony with these pump parameters is critical for ensuring optimal performance and system longevity.

Benefits of Surge Tanks: Ensured System Reliability

In the realm of hydraulic systems, surge tanks hold a pivotal role in safeguarding equipment and ensuring uninterrupted operation. Their unique design and strategic placement allow them to mitigate pressure variations, effectively preventing the dreaded water hammer effect.

No More Water Hammer, No More Worries

Water hammer is a destructive force that can wreak havoc on pipelines, pumps, and other components. It occurs when a sudden change in flow velocity creates a shock wave that travels through the system. This shock wave can cause vibrations, damage equipment, and even lead to catastrophic failures. Surge tanks act as buffers, absorbing the excess pressure and preventing it from propagating throughout the system. By taming water hammer, surge tanks ensure the smooth and reliable operation of hydraulic systems.

A Symphony of Silence, a Haven of Comfort

Surge tanks not only prevent damage but also contribute to a more comfortable working environment. Without surge tanks, the sudden release of pressure during pump shutdowns or valve closures can create loud and disruptive noises. However, surge tanks act as silencers, absorbing the pressure fluctuations and reducing noise levels. This not only provides a more pleasant work atmosphere but also helps protect hearing and prevent noise-related health issues.

Protecting Your Investment, Preserving Performance

When it comes to hydraulic systems, equipment is paramount. Surge tanks play a crucial role in protecting pumps, valves, and other components from damage caused by pressure surges. By absorbing excess pressure and preventing water hammer, surge tanks extend the lifespan of equipment, minimizing maintenance costs and maximizing uptime. This proactive approach to system protection ensures reliable operation and optimal performance for years to come.

Potential Drawbacks of Surge Tanks: Cost and Limitations

While surge tanks offer significant benefits in mitigating pressure surges, they also come with certain potential drawbacks that should be considered before implementation.

Cost Implications:

Installing and maintaining surge tanks can be a substantial expense. The tanks themselves can be costly to fabricate and may require specialized materials or configurations depending on the system requirements. Additionally, the installation process can involve significant labor and equipment, especially in locations with limited access or space constraints.

Space Requirements:

Surge tanks typically require a significant amount of space, which can be a limiting factor in densely populated areas or facilities with limited available space. The size of the tank is directly related to the volume of fluid it needs to accommodate, and larger tanks require more real estate. This can become a challenge in retrofitting existing systems or installing surge tanks in tightly packed industrial settings.

Cavitation Risks:

Under certain operating conditions, surge tanks can experience cavitation, which occurs when the pressure inside the tank drops below the vapor pressure of the fluid. This can result in the formation of vapor bubbles, which can collapse violently and cause damage to the tank’s interior surfaces. Cavitation can be particularly problematic in closed surge tanks, where the pressure fluctuations are more pronounced. Proper design and sizing of the tank is crucial to mitigate the risk of cavitation.

Applications of Surge Tanks: Diverse Industries

In the realm of hydraulic systems, surge tanks play a pivotal role in mitigating pressure surges and safeguarding equipment from the damaging effects of water hammer. These versatile devices find applications in a wide range of industries, ensuring reliable and efficient operation.

-

Water Supply Systems:

Surge tanks are crucial components in water distribution networks. They prevent pressure fluctuations caused by sudden changes in demand. By absorbing excess pressure during peak consumption, surge tanks protect pipelines and fittings from ruptures. -

Hydroelectric Power Plants:

In hydroelectric power plants, surge tanks regulate pressure in the penstock, the conduit that carries water to the turbine. They absorb excess pressure during sudden load variations, preventing damage to the turbine and other equipment. -

Pipelines:

Surge tanks are employed along pipelines to minimize pressure variations caused by rapid changes in flow rate. In long pipelines, surge tanks prevent excessive pressure buildup or collapse due to fluid inertia. -

Industrial Processes:

In various industrial applications, surge tanks are used to stabilize pressure in process piping systems. They reduce pressure surges caused by pump startup or shutdown, safeguarding sensitive equipment and ensuring optimal process performance.

The benefits of surge tanks extend beyond pressure surge mitigation. They also reduce noise levels, protect equipment from cavitation, and improve overall system reliability. However, it’s important to consider the cost implications, space requirements, and potential drawbacks before implementing surge tanks in a specific application.