Expert Guide To Latex Glove Manufacturing: Process And Best Practices

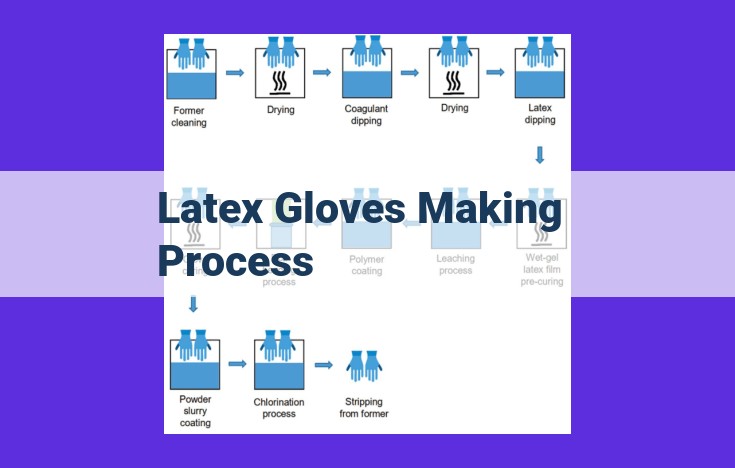

The latex glove making process involves: compounding raw materials to form a latex compound; calendering to shape latex sheets; extruding latex into molds to create glove shapes; dipping molds into latex to form a thin layer; drying to evaporate moisture; curing to enhance strength and elasticity; stripping gloves from molds; beading to seal cuffs; and quality control for standards compliance.

The Paramount Importance of Latex Gloves: Beyond the Medical Realm

Latex gloves serve as invaluable safeguards in the healthcare arena, protecting both medical practitioners and patients from the transmission of harmful pathogens. Their meticulous crafting ensures a barrier against bodily fluids, minimizing the risk of infection.

Beyond healthcare, latex gloves play a crucial role in diverse industries. _In food preparation, _they guard against contamination, preserving food safety and hygiene. _In laboratory settings, _they shield researchers from hazardous chemicals, safeguarding their well-being.**

The manufacturing process of latex gloves is an intricate blend of science and precision. Raw materials, including natural rubber, are meticulously combined to create a uniform latex compound. This compound is then shaped into thin sheets through a process known as calendering. Subsequently, molds are employed in the extrusion process, shaping the latex into the familiar glove form.

The immersion of these molds into a latex bath creates a thin, even layer on their surfaces. Curing involves heat treatment to enhance strength and elasticity, rendering the gloves more durable and flexible.

Rigorous quality control measures ensure that each glove meets stringent standards. The final step of packaging safeguards the gloves during storage and distribution, ensuring their integrity until they reach the end-user.

The Building Blocks of Latex Gloves: Raw Materials and Compounding

In the realm of healthcare and beyond, latex gloves stand as indispensable guardians of hygiene. Their ability to protect both the wearer and those they serve stems from the meticulous process of their creation. At the heart of this process lies the careful selection and blending of raw materials.

Natural Rubber, the Foundation

The primary ingredient in latex gloves is natural rubber, a resilient material derived from the milky sap of rubber trees. This sap, known as latex, contains a high concentration of polyisoprene, a type of polymer that gives rubber its characteristic elasticity and strength.

Additives Enhance Performance

To enhance the properties of natural rubber, a range of additives are incorporated. These include:

- 硫:strengthens the latex by cross-linking the polyisoprene chains.

- Antioxidants:prevent the latex from degrading over time.

- Accelerators:speed up the vulcanization process, which further strengthens the latex.

- Fillers:add bulk and improve the texture of the gloves.

Blending for Homogeneity

The raw materials are carefully weighed and mixed to create a homogeneous compound. This ensures that the gloves have consistent properties throughout, guaranteeing their effectiveness and safety. The mixing process involves several stages:

- Mastication:breaks down the natural rubber into smaller particles.

- Banbury mixing:mixes the rubber with the additives in a high-shear mixer.

- Compounding:further refines the mixture until it reaches the desired consistency and properties.

The resulting compound is now ready for the next stage in the glove-making process: calendering.

Mixing for Uniformity: Ensuring Flawless Latex Gloves

In the realm of latex glove production, achieving uniformity is paramount. A homogeneous compound is the foundation upon which high-quality gloves are built. To ensure this uniformity, a meticulous mixing process is employed.

Imagine a vast cauldron filled with raw latex materials. These materials, possessing varying viscosities and compositions, must be harmoniously blended to create a uniform compound. The first step involves stirring, a gentle rotation that gently stirs the mixture to prevent settling. As the stirring intensifies, agitators, like mechanical maestros, churn the latex, creating a whirlpool of movement. The aim is to disperse the raw materials evenly, ensuring that each ingredient is thoroughly incorporated.

Next comes homogenization, a more forceful technique that breaks down any remaining clumps or agglomerations. Powerful machines, known as homogenizers, subject the latex to high-pressure forces, shearing and dispersing the mixture into a smooth, uniform consistency. The resulting compound is a symphony of ingredients, each playing its role in creating the desired Eigenschaften of the gloves.

This meticulous mixing process is essential for ensuring the integrity, strength, and flexibility of latex gloves. A uniform compound guarantees that the gloves will withstand the demands of various industries, from healthcare to food handling, without compromising protection or comfort. It is a testament to the precision and dedication required to produce latex gloves that meet the highest standards of quality and performance.

Calendering: Sculpting the Sheets

As the latex compound undergoes a metamorphosis, it enters the calendering stage, where it’s transformed into pliable sheets or films. This process involves a series of rollers that work in unison to shape the liquid latex into a thin, uniform material.

Giant rollers, adorned with mirror-like surfaces, await the latex compound. The compound, still in its viscous state, is fed into the rollers, which rotate in opposing directions. With each rotation, the compound is sandwiched between these mighty cylinders, gradually becoming thinner and more malleable.

Layer by layer, the latex is pressed and rolled, its thickness meticulously controlled. The rollers’ relentless pressure expels any imperfections, creating a uniform sheet of latex. This process not only shapes the latex but also enhances its strength and durability.

Once the desired thickness is achieved, the latex sheet emerges from the calendering rollers, ready for the next stage of its journey. These sheets will soon be transformed into the gloves that protect our hands and safeguard our health.

Extrusion: Molding the Gloves

- Discuss the use of molds and the extrusion process to shape the latex into the desired glove shape.

Extrusion: Molding the Gloves

In the realm of latex glove manufacturing, extrusion emerges as a pivotal technique for shaping the raw latex into the familiar form that safeguards our hands. This intricate process employs precisely engineered molds and an extrusion machine to transform the viscous latex compound into the desired glove shape.

The molds, meticulously crafted to mirror the intricate contours of the human hand, serve as the blueprints for the gloves’ final form. As the latex compound flows steadily through the extrusion machine, it encounters the molds, gently filling their cavities. With meticulous precision, the latex conforms to every nook and cranny, capturing the intricate details of the hand’s anatomy.

The extrusion technique offers a remarkable degree of versatility, allowing for the production of gloves in a wide array of sizes, thicknesses, and textures. By carefully adjusting the pressure and flow rate of the latex compound, manufacturers can tailor the gloves to meet the specific demands of different applications, from delicate surgical procedures to rugged industrial tasks.

Once the latex has fully filled the molds, it enters a curing phase, where it undergoes a delicate balance of heat and time. This crucial step transforms the soft and pliable latex into a durable and resilient material, enhancing its strength, elasticity, and resistance to punctures and tears.

The result of this intricate process is a glove that seamlessly conforms to the wearer’s hand, providing an unparalleled level of protection and comfort. From the delicate touch of a surgeon to the robust grip of an industrial worker, latex gloves safeguard our hands, enabling us to perform our tasks with confidence and dexterity.

Dipping: Creating the Thin Layer

- Explain the immersion process, where the molds are dipped into a latex bath to create a thin, even layer on their surfaces.

Dipping: The Art of Crafting a Thin, Protective Layer

In the intricate process of latex glove manufacturing, the dipping stage holds a pivotal role in shaping the thin, protective barrier that shields us from harmful substances. It is here that the foundation for the glove’s durability and flexibility is meticulously laid.

Imagine a majestic ballet, as the molds, like graceful dancers, gently descend into a warm bath of latex. The liquid latex, adorned with intricate compounds, envelops the molds, caressing their surfaces and creating a seamless embrace. With each dip, a delicate layer of latex adheres to the mold, forming the nascent glove.

Precision is paramount during this immersion process. Meticulous control over factors such as temperature, viscosity, and immersion time ensures that the thickness and uniformity of the latex layer meet the exacting standards required for effective protection.

As the molds emerge from their latex bath, they carry with them a fragile silhouette of the glove to be. This thin, pliable layer serves as the foundation upon which the remaining manufacturing steps will build, transforming it into the robust barrier that safeguards our hands.

Drying: Evaporating the Excess Moisture

As the latex gloves emerge from the dipping process, they are still wet with excess moisture and solvents. To attain their final form, they must undergo a crucial step called drying. This process is essential for solidifying the latex film and ensuring the gloves’ pliability.

During drying, the gloves are subjected to warmth or airflow to accelerate the evaporation of the solvents and excess water. The temperature and duration of the drying period are carefully controlled to prevent damage to the latex and maintain the gloves’ desired properties.

The drying process is a critical stage in the production of latex gloves. It is only through the precise evaporation of moisture that the gloves achieve their optimal strength, elasticity, and comfort.

Curing: Enhancing Strength and Elasticity

The journey of latex gloves does not end with their formation. To achieve the robustness and flexibility they are renowned for, they undergo a critical transformation process called curing. This heat treatment is the final touch that polymerizes and cross-links the latex molecules, forging a stronger and more resilient material.

Imagine the latex glove as a loose network of long, tangled chains. During curing, these chains undergo a chemical reaction under the influence of heat. They intertwine and bond together, forming a more tightly knit structure, much like the weave of a strong fabric. This process significantly increases the gloves’ tensile strength.

In addition to strength, curing also enhances the elasticity of the gloves. As the latex chains become more tightly bound, the material gains the ability to stretch and recoil without losing its shape. This flexibility is essential for comfortable and effective use in various applications.

The curing process is a delicate balance, as excessive heat can damage the gloves. Manufacturers carefully control the temperature and duration of the treatment to achieve the optimal combination of strength and elasticity. This ensures that the gloves can withstand the rigorous demands of healthcare, industrial, and household use while maintaining their protective qualities and user comfort.

Stripping: Liberating the Gloves from Their Molds

Once the latex has been cured, the molds are ready to surrender their precious cargo. A skilled worker deftly reaches into the mold, their fingers expertly navigating the intricate contours. With a gentle coaxing motion, they peel away the latex glove, leaving behind any excess latex that may have clung to the mold’s surface.

This peeling process requires both precision and dexterity. The worker must carefully remove the glove without tearing it, ensuring its integrity remains intact. Any excess latex can be easily trimmed away, leaving behind a pristine, ready-to-wear glove.

The stripped gloves are then carefully inspected to ensure they meet the highest standards of quality. Each glove is meticulously examined for any imperfections or flaws, ensuring it provides the utmost protection and comfort to its wearer.

Beading: Ensuring Impermeable Seals

After forming the individual gloves, the next crucial step in the latex glove manufacturing process is beading. This process involves joining and sealing the edges of the glove cuffs to prevent leakage and maintain the glove’s integrity.

Joining Techniques

To join the edges of the glove cuffs, manufacturers use a variety of techniques, including:

-

Overlapping: The edges of the cuff are overlapped and heat-sealed together, creating a double layer for added strength.

-

Welding: Ultrasonic waves or heat is used to fuse the cuff edges together, resulting in a seamless seal.

-

Gluing: A specialized adhesive is applied to the edges of the cuff, which are then pressed together to form a tight bond.

Sealing Techniques

Once the edges are joined, the seams are further sealed to prevent any potential leakage. This is typically achieved using:

-

Heat sealing: The seams are exposed to high temperatures, causing the latex to melt and fuse together, creating a waterproof barrier.

-

Solvent bonding: A solvent is applied to the seams, which dissolves the latex, allowing it to flow together and form a chemical bond.

Quality Control

Beading plays a critical role in ensuring the quality and integrity of latex gloves. To maintain high standards, manufacturers perform rigorous testing on all beaded gloves to check for:

-

Leakproofness: Gloves are filled with water and pressurized to ensure they remain impermeable.

-

Seal strength: The strength of the beading seal is tested to ensure it can withstand repeated stretching and flexing.

-

Visual inspection: Gloves are visually inspected for any imperfections or defects that could compromise their sealing capabilities.

Beading is an essential step in the latex glove manufacturing process that ensures the protection and safety of healthcare professionals and individuals in various industries. By joining and sealing the glove cuffs, manufacturers create a barrier against pathogens and prevent leakage, maintaining the integrity of the gloves and their ability to protect against contamination.

Quality Control: Ensuring Uncompromising Standards

In the realm of healthcare and beyond, latex gloves serve as a crucial defense against microscopic threats. To guarantee that these gloves meet the highest standards, manufacturers adhere to rigorous quality control measures.

Testing and Inspection

Every batch of latex gloves undergoes a battery of tests to assess their durability, elasticity, and resistance to punctures. These tests ensure that the gloves provide reliable protection while remaining comfortable to wear. Additionally, visual inspections scrutinize the gloves for any imperfections or defects that could compromise their effectiveness.

Measurement Standards

Beyond physical testing, manufacturers also adhere to strict measurement standards. Precise gauges determine the thickness of the gloves, ensuring they provide adequate protection without sacrificing dexterity. Length and width specifications guarantee a snug fit for all users, preventing gaps that could allow contaminants to penetrate.

Certifications and Accreditations

To demonstrate their commitment to quality, manufacturers seek certifications from reputable organizations. These certifications attest to the gloves’ compliance with industry regulations and international standards. Accreditation by bodies such as the FDA, CE, or ISO 9001 provides assurance that the gloves meet the highest benchmarks for safety and efficacy.

By adhering to stringent quality control protocols, manufacturers ensure that every pair of latex gloves meets the unwavering standards of healthcare professionals, patients, and individuals demanding the utmost protection.

Packaging: Preserving Integrity for Distribution and Sale

Ensuring the pristine condition of latex gloves throughout distribution and sale is paramount for maintaining their functionality and protective properties. A meticulous packaging process safeguards the gloves against external influences, ensuring they reach the end-user in optimal condition.

Controlled Storage:

Gloves are carefully stored in temperature-controlled environments to prevent damage. Extremes in temperature can weaken the latex, affecting its elasticity and protective abilities. Proper storage ensures the gloves retain their integrity and performance.

Protective Barriers:

Gloves are packaged in individual, airtight containers to provide a protective barrier against external contaminants. These containers prevent exposure to moisture, dust, and other particles that could compromise the gloves’ hygiene and protective effectiveness.

Labeling and Identification:

The packaging clearly identifies the glove type, size, and any additional features. This information assists in inventory management, ensures proper usage, and meets regulatory requirements. Accurate labeling allows healthcare professionals to select the appropriate gloves for specific procedures and industries.

Distribution and Handling:

During distribution, gloves are carefully handled to avoid punctures or tears. They are packed in sturdy containers that provide protection during transportation and storage. Responsible handling ensures the gloves remain intact and ready for use.

End-User Protection:

The packaging not only protects the gloves but also serves as a hygiene safeguard. By providing individual, sealed containers, gloves remain sterile until they are ready to be used. This reduces the risk of contamination and ensures the safety of healthcare workers and patients.

The meticulous packaging process ensures that latex gloves reach their destination in pristine condition, preserving their protective qualities and providing healthcare professionals with the confidence to safeguard themselves and their patients.