Unveil Hot Gas Bypass: The Ultimate Guide To Enhanced Refrigeration

Ultimate Guide to Unlocking Hot Gas Bypass Secrets

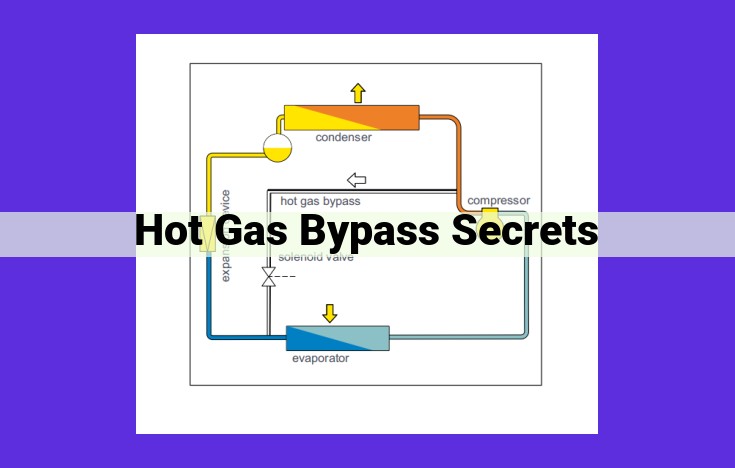

Hot gas bypass is a technique that enhances the efficiency and capacity control of refrigeration systems. By introducing a bypass line and valve, a portion of the hot gas from the compressor is directed back to the evaporator, reducing the amount of refrigerant flowing through the condenser. This influences system capacity, desuperheating, superheating, and efficiency optimization. Understanding hot gas bypass not only allows troubleshooting potential issues like overheating and insufficient cooling but also unlocks its potential benefits for refrigeration professionals.

Ultimate Guide to Unlocking Hot Gas Bypass Secrets

Unlocking the secrets of hot gas bypass is crucial for refrigeration professionals. Let’s delve into the fundamentals, starting with the components of a refrigeration system.

Components of a Refrigeration System: A Symphony of Cooling

A refrigeration system resembles a well-coordinated orchestra. The evaporator plays the role of a vocalist, absorbing heat from the surrounding environment. The compressor, like a conductor, compresses the refrigerant and pumps it through the system. The condenser, akin to a backup singer, releases the heat extracted by the evaporator. Finally, the throttling valve, acting as a tuner, reduces pressure and temperature before the refrigerant re-enters the evaporator.

Hot Gas Bypass: The Maestro of Capacity Control

Hot gas bypass is a technique that allows us to control the cooling capacity of a refrigeration system. It involves diverting a portion of the hot, high-pressure gas from the compressor into the suction line of the system. This bypassed gas mixes with the low-pressure, cold gas returning from the evaporator, reducing its temperature and thus the system’s capacity.

Influence on System Performance: A Delicate Balance

Hot gas bypass plays a pivotal role in optimizing system performance. By reducing capacity, it can prevent overcooling and ensure efficient operation. Additionally, it desuperheats the refrigerant, which enhances the efficiency of the condenser. Conversely, excessive hot gas bypass can lead to superheating, reducing the effectiveness of the evaporator.

Troubleshooting Hot Gas Bypass Issues: Detecting Discord

If you encounter issues with your refrigeration system, hot gas bypass might be the culprit. Overheating, insufficient cooling, or refrigerant flow imbalance could indicate problems with this technique. Determine the root cause and implement appropriate solutions, such as adjusting the bypass valve or checking for leaks.

Mastering hot gas bypass is essential for refrigeration professionals. It empowers them to fine-tune cooling capacity, optimize system performance, and resolve issues effectively. Understanding this technique not only enhances refrigeration expertise but also safeguards the efficiency and reliability of your cooling systems.

Ultimate Guide to Unlocking Hot Gas Bypass Secrets:

In the realm of refrigeration, the concept of hot gas bypass holds immense significance. It’s a technique that allows you to finely tune your system, unlocking a world of possibilities for capacity control and performance optimization.

Delving into the Refrigeration System’s Core:

Before we delve into the secrets of hot gas bypass, it’s essential to understand the basic components of a refrigeration system. The evaporator works its magic by absorbing heat from the surrounding environment, turning it into a cool breeze. The compressor then compresses the refrigerant gas, increasing its pressure and temperature. Next up is the condenser, where the refrigerant releases its heat, transforming back into a liquid. Finally, the throttling valve controls the flow of refrigerant, maintaining the system’s equilibrium.

Hot Gas Bypass: The Capacity Control Master:

Hot gas bypass is a clever trick that involves diverting a portion of the hot, high-pressure refrigerant gas from the compressor directly into the evaporator. This diversion creates a bypass line and a bypass valve, allowing you to control the amount of refrigerant entering the evaporator.

By adjusting the bypass valve, you effectively manipulate the system’s capacity. Increasing the bypass flow reduces the amount of refrigerant reaching the evaporator, thereby decreasing the system’s cooling capacity. Conversely, reducing the bypass flow allows more refrigerant to enter the evaporator, boosting the system’s capacity.

Unveiling the Impact on System Performance:

Hot gas bypass plays a pivotal role in shaping the system’s performance. By adjusting the bypass flow, you can:

- Reduce capacity: When you increase the bypass flow, you essentially “throttle back” the system, reducing its overall cooling capacity.

- Desuperheat the refrigerant: As the hot refrigerant gas bypasses the condenser, it loses some of its heat, resulting in a lower temperature at the evaporator inlet.

- Superheat the refrigerant: Since less refrigerant enters the evaporator, the refrigerant leaving the evaporator may have a higher temperature, known as superheat.

- Optimize efficiency: Fine-tuning the bypass flow can help optimize system efficiency by ensuring that the evaporator is operating at its optimal conditions.

Troubleshooting Hot Gas Bypass Hiccups:

While hot gas bypass is a powerful tool, it can sometimes encounter hiccups. Here are some common issues and their solutions:

- Overheating: Excessive bypass flow can lead to overheating of the condenser and compressor, as the hot refrigerant gas isn’t properly cooled in the condenser.

- Insufficient cooling: Conversely, insufficient bypass flow can result in insufficient cooling capacity, as the evaporator is starved of refrigerant.

- Refrigerant flow imbalance: Improper bypass flow can disrupt the refrigerant flow balance, leading to uneven cooling and reduced efficiency.

For refrigeration professionals, understanding hot gas bypass is like unlocking a secret superpower. It empowers you to control system capacity, optimize performance, and troubleshoot issues with finesse. Whether you’re dealing with large commercial systems or compact residential units, mastering hot gas bypass will elevate your skills to the next level.

Ultimate Guide to Unlocking Hot Gas Bypass Secrets

Components of a Refrigeration System

A refrigeration system consists of four main components: an evaporator, compressor, condenser, and throttling valve. The evaporator absorbs heat from the refrigerated space, the compressor pressurizes the refrigerant, the condenser releases heat to the surrounding environment, and the throttling valve controls the flow of refrigerant into the evaporator.

Hot Gas Bypass and Capacity Control

Hot gas bypass is a technique used to control the capacity of a refrigeration system. It involves bypassing a portion of the high-pressure refrigerant gas from the compressor outlet to the evaporator inlet.

Bypass Line and Bypass Valve:

The bypass line is a pipe that connects the compressor outlet to the evaporator inlet. The bypass valve regulates the flow of refrigerant through the bypass line.

Impact on System Capacity:

By diverting hot gas from the compressor to the evaporator, hot gas bypass reduces the amount of refrigerant flowing through the condenser. This, in turn, lowers the system’s capacity.

Influence of Hot Gas Bypass on System Performance

- Capacity Reduction: As discussed earlier, hot gas bypass primarily serves to reduce system capacity. This is useful in situations where the cooling demand fluctuates or when the system is oversized.

- Desuperheating: Hot gas bypass can also help to desuperheat the refrigerant leaving the compressor. This means reducing its temperature and pressure before it enters the condenser, improving the efficiency of the condenser.

- Superheating: In some cases, hot gas bypass can introduce additional superheat into the system. Superheat refers to the temperature difference between the refrigerant and the evaporator surface. This can be advantageous in certain applications where it is desirable to increase the evaporator temperature.

- Efficiency Optimization: By controlling the system’s capacity and optimizing the refrigerant’s properties, hot gas bypass can contribute to overall system efficiency improvements.

Troubleshooting Hot Gas Bypass Issues

- Overheating: If the bypass valve is open too wide, too much hot gas may be bypassed to the evaporator, leading to overheating of the compressor.

- Insufficient Cooling: If the bypass valve is closed too tightly, too little hot gas may be bypassed, resulting in insufficient cooling.

- Refrigerant Flow Imbalance: Improper sizing of the bypass line or valve can create a flow imbalance in the system, causing inefficient operation or component damage.

Impact on capacity reduction, desuperheating, superheating, and efficiency optimization.

3. Influence of Hot Gas Bypass on System Performance

The magic of hot gas bypass lies in its ability to control system capacity, allowing technicians to fine-tune refrigeration systems to meet specific cooling needs. By manipulating the flow of hot gas, technicians can reduce capacity, desuperheat, and superheat refrigerants, all while optimizing system efficiency.

Capacity Reduction

Hot gas bypass acts like a throttle valve, reducing the flow of refrigerant into the evaporator. By doing so, it effectively lowers the system’s cooling capacity, making it perfect for adjusting to fluctuating load demands. During periods of low cooling demand, hot gas bypass can save energy and prevent over-cooling.

Desuperheating and Superheating

As refrigerant exits the compressor, it’s often superheated, carrying excess heat that can damage system components. But wait, enter hot gas bypass! It desuperheats the refrigerant by mixing it with cooler gas, protecting your system from harm. On the flip side, hot gas bypass can also help superheat refrigerant when necessary, ensuring optimal evaporator performance.

Efficiency Optimization

Finding the perfect balance between capacity and efficiency is a delicate dance. Hot gas bypass helps strike that harmony by reducing energy consumption while maintaining desired cooling levels. By fine-tuning the flow of refrigerant, you conserve energy and keep your system running smoothly.

Ultimate Guide to Unlocking Hot Gas Bypass Secrets

1. Components of a Refrigeration System

Imagine your refrigeration system as a team of four players: the evaporator, compressor, condenser, and throttling valve. Each player has a specific role to ensure your system functions flawlessly.

2. Hot Gas Bypass and Capacity Control

Hot gas bypass is like a secret weapon that allows you to fine-tune your refrigeration system’s capacity. It works by diverting some of the high-pressure, hot refrigerant leaving the condenser back into the compressor. This bypass line helps control the amount of refrigerant entering the evaporator, effectively adjusting the cooling capacity.

3. Influence of Hot Gas Bypass on System Performance

By manipulating the hot gas bypass, you can:

- Reduce capacity: When you want to decrease the cooling power, you increase the flow of hot refrigerant.

- Desuperheat: Hot gas bypass helps remove excess heat from the refrigerant, preventing condensation in the compressor.

- Superheat: It also prevents refrigerant from entering the compressor in a liquid state, ensuring efficient operation.

- Optimize efficiency: Balancing hot gas bypass improves the overall energy consumption of your refrigeration system.

4. Troubleshooting Hot Gas Bypass Issues

Like any mechanical system, hot gas bypass can encounter issues that disrupt your refrigeration performance. Some common problems include:

Overheating**: This occurs when the bypass valve is closed or restricted, causing the compressor to overheat.

Insufficient cooling**: If the bypass valve is open too far, the system may not cool adequately due to reduced refrigerant flow.

Refrigerant flow imbalance**: This can lead to system instability and poor performance.

Understanding hot gas bypass is crucial for any refrigeration professional. It provides numerous benefits, including:

- Precise capacity control

- Improved system performance

- Enhanced troubleshooting capabilities

Embrace the secrets of hot gas bypass to unlock the full potential of your refrigeration system and ensure its efficient and reliable operation.

Ultimate Guide to Unlocking Hot Gas Bypass Secrets

Troubleshooting Hot Gas Bypass Issues

Hot gas bypass is a crucial component in refrigeration systems, but it can sometimes lead to unexpected issues. Let’s delve into the potential problems and explore some effective solutions:

Overheating Compressor: When the hot gas bypass valve malfunctions, it can lead to an excessive flow of hot gas into the compressor. This overheats the compressor, reducing its efficiency and lifespan. Replace or repair the faulty bypass valve promptly to prevent further damage.

Insufficient Cooling: An insufficient flow of hot gas through the bypass valve can result in poor cooling performance. This occurs when the bypass valve is clogged or malfunctioning. Cleaning or adjusting the valve, or if necessary, replacing it can restore optimal cooling capacity.

Refrigerant Flow Imbalance: A malfunctioning hot gas bypass valve can disrupt the delicate refrigerant flow balance in the system. This can lead to uneven cooling throughout the system, affecting performance and potentially causing component damage. Ensure proper refrigerant flow by checking the bypass valve, inspecting the lines, and adjusting or replacing faulty components.

Addressing Hot Gas Bypass Issues

To prevent and address hot gas bypass issues, regular maintenance and inspections are crucial. Monitor system performance, including compressor temperature, cooling capacity, and refrigerant flow. Promptly address any abnormalities to prevent minor issues from escalating into major problems.

Remember, a well-functioning hot gas bypass system is essential for efficient refrigeration operation. By understanding the potential problems and embracing proactive maintenance, you can ensure that your refrigeration system operates at its peak performance for years to come.

Recap of the importance of understanding hot gas bypass for refrigeration professionals.

Ultimate Guide to Unlocking Hot Gas Bypass Secrets

Step into the world of refrigeration, where understanding the intricacies of hot gas bypass can elevate your expertise to new heights. This essential mechanism plays a pivotal role in capacity control and performance optimization within refrigeration systems.

Components of a Refrigeration System

Unveiling the essential components of a refrigeration system:

- Evaporator: The heart of the system, where heat is extracted from the refrigerated space.

- Compressor: The workhorse that compresses the refrigerant vapor, increasing its pressure and temperature.

- Condenser: A heat exchanger that dissipates heat from the refrigerant vapor, condensing it into a liquid.

- Throttling valve: A gatekeeper that controls the flow of refrigerant into the evaporator.

Hot Gas Bypass and Capacity Control

Hot gas bypass, a crucial mechanism, allows a portion of the hot gas from the compressor outlet to bypass the condenser, mixing with the refrigerant exiting the evaporator. This clever technique reduces the refrigerating capacity of the system, making it highly adaptable to varying cooling demands.

Influence of Hot Gas Bypass on System Performance

The impact of hot gas bypass is far-reaching:

- Capacity reduction: By adjusting the amount of hot gas bypass, the system can fine-tune its cooling capability to meet the specific needs of the refrigerated space.

- Desuperheating: The hot gas bypass can prevent overheating of the compressor by reducing the temperature of the refrigerant vapor entering the compressor.

- Superheating: By adjusting the bypass flow, the system can optimize superheating, ensuring efficient heat transfer in the evaporator.

- Efficiency optimization: Hot gas bypass allows for more efficient use of refrigerant, reducing energy consumption and operating costs.

Troubleshooting Hot Gas Bypass Issues

Understanding hot gas bypass is not just about the theory; it’s also essential for troubleshooting. Improper operation can lead to issues such as:

- Overheating: Excessive hot gas bypass can starve the condenser, causing the compressor to overheat.

- Insufficient cooling: Insufficient hot gas bypass can lead to poor cooling performance.

- Refrigerant flow imbalance: An incorrectly adjusted bypass can cause refrigerant flow imbalances, affecting system efficiency.

By recognizing these potential problems and their causes, refrigeration professionals can quickly identify and resolve issues, ensuring the smooth operation of their systems.

Mastering the secrets of hot gas bypass is a must for refrigeration professionals. This ingenious mechanism provides exceptional control over refrigeration capacity, enabling systems to adapt to changing demands while maintaining optimal performance. By unlocking the potential of hot gas bypass, refrigeration professionals can maximize efficiency, minimize costs, and ensure the reliable operation of refrigeration systems.

Hot Gas Bypass: Unlocking Refrigeration’s Hidden Potential

In the realm of refrigeration, the concept of hot gas bypass holds immense power, often shrouded in mystery. But like a well-kept secret, once unlocked, it unravels a world of efficiency, performance, and control that can transform the performance of any refrigeration system.

Capacity Control: Precision at Your Fingertips

When faced with fluctuating cooling demands, hot gas bypass grants you unprecedented capacity control. By diverting a portion of hot compressed refrigerant back to the evaporator, you can effectively reduce the system’s cooling output, matching it to the varying needs of your application. This precise regulation ensures optimal cooling without overworking the compressor or wasting energy.

Performance Optimization: A Symphony of Efficiency

Hot gas bypass plays a pivotal role in performance optimization. Its ability to control desuperheating and superheating ensures proper refrigerant flow and optimal heat transfer. By preventing the entry of excessive superheated vapor into the compressor, bypasses reduce wear and improve compressor efficiency. Additionally, by reducing superheating, they minimize condenser load and enhance system efficiency.

Troubleshooting: A Lifeline for Refrigeration Woes

In the unfortunate event of refrigeration issues, hot gas bypass can be your lifeline. By understanding its impact on system performance, you gain the ability to troubleshoot common problems effectively. If you encounter overheating, insufficient cooling, or refrigerant flow imbalance, tracing the root cause to the hot gas bypass system can lead you to quick and precise solutions, saving you time and headaches.

For refrigeration professionals, mastering hot gas bypass is akin to unlocking a treasure trove of optimization possibilities. It empowers you with capacity control, performance optimization, and troubleshooting abilities that elevate your refrigeration systems to unparalleled levels of efficiency and reliability. Embrace the secrets of hot gas bypass and witness the transformative impact it holds for your refrigeration operations.