Pinion Angle Optimization: Essential Guide For Lowered Truck Owners

Lowered truck owners must understand pinion angle, the angle between the driveshaft and differential, to optimize driveline alignment. Lowering impacts ride height and changes pinion angle, leading to driveline vibrations. Correcting the pinion angle with shims or adjustable control arms is crucial to prevent misalignment and driveline issues. Measuring pinion angle with a specialized tool ensures proper adjustment, which enhances handling, reduces noise, improves fuel efficiency, and extends driveline life. Misconceptions about pinion angle invariance and adjustment difficulty should be debunked to empower truck owners with knowledge for maintaining optimal driveline performance.

Understanding Pinion Angle: A Comprehensive Guide for Lowered Trucks

Introduction

For enthusiasts who desire to enhance the aesthetics and performance of their lowered trucks, understanding pinion angle is crucial. This guide will delve into the complexities of pinion angle, its impact on lowered trucks, and the significance of proper adjustment.

What is Pinion Angle, and Why Does it Matter?

Pinion angle refers to the angle at which the driveshaft connects to the differential. In lowered trucks, the driveshaft must negotiate a steeper angle to align with the lowered suspension. An incorrect pinion angle can lead to driveline vibrations, misalignment, and premature wear.

Impact of Lowering on Pinion Angle

When a truck is lowered, the differential is effectively raised, altering the driveshaft angle. This can cause the driveshaft to vibrate and generate excessive noise. Furthermore, misalignment of the driveline components can lead to accelerated wear and reduced fuel efficiency.

Significance of Pinion Angle Adjustment

Adjusting the pinion angle ensures optimal alignment between the driveshaft, differential, and transmission. It minimizes vibrations, reduces driveline wear, and enhances overall performance. Neglecting pinion angle adjustment can have severe consequences for the driveline and driving experience.

Methods for Adjusting Pinion Angle

Driveline angle shims: Shims are thin metal spacers inserted between the differential and the axle housing. By adjusting the thickness and placement of shims, the pinion angle can be altered.

Adjustable control arms: These specialized suspension components allow for precise adjustments of the pinion angle. They provide a wider range of adjustability compared to shims.

Measuring Pinion Angle

Accurate pinion angle measurement is essential. A pinion angle finder, a specialized tool, is used to measure the angle between the driveshaft and the differential. Proper measurement ensures precise adjustment and optimal driveline performance.

Ideal Pinion Angle for Lowered Trucks

The ideal pinion angle for lowered trucks varies depending on the specific vehicle and driveline configuration. It is best determined by consulting manufacturer specifications or seeking advice from experienced mechanics.

Consequences of Incorrect Pinion Angle

Improper pinion angle can have several negative consequences:

- Driveline noise: Excessive vibrations can generate unpleasant noise.

- Driveline wear: Misalignment accelerates wear on driveline components.

- Reduced fuel efficiency: Incorrect pinion angle can increase drag and reduce fuel economy.

Benefits of Proper Pinion Angle

Correct pinion angle adjustment offers several benefits:

- Improved handling: Proper alignment enhances handling and stability.

- Reduced driveline noise: Minimized vibrations reduce noise levels.

- Extended driveline life: Optimal alignment extends the lifespan of driveline components.

Debunking Misconceptions

- Pinion angle is unaffected by lowering: This is a common misconception. Lowering a truck inevitably alters the driveshaft angle.

- Pinion angle adjustment is inherently difficult: With proper knowledge and tools, pinion angle adjustment can be a manageable task.

Impact of Lowering on Pinion Angle

Introduction:

Lowering a truck may seem like a simple modification, but it can have significant effects on the vehicle’s suspension and driveline angles. One crucial angle that requires attention is the pinion angle. Understanding how lowering affects the pinion angle is essential for ensuring optimal driveline performance.

Ride Height and Suspension:

When a truck is lowered, the distance between the axle and the frame is reduced. This change in ride height alters the suspension geometry, which affects the angles of the driveshaft, differential, and pinion. As the suspension is lowered, the driveshaft angle becomes steeper.

Pinion Angle Changes:

The pinion angle is the angle at which the pinion gear on the differential meets the ring gear on the axle. This angle is crucial because it ensures that the driveshaft rotates smoothly, minimizes vibrations, and reduces wear on the differential gears.

Lowering a truck can cause the pinion angle to become too steep or shallow. If the angle is too steep, it can put excessive stress on the driveshaft and differential, leading to vibrations and premature failure. Conversely, a shallow pinion angle can reduce the driveline’s efficiency and increase fuel consumption.

Conclusion:

Understanding the impact of lowering on the pinion angle is crucial for ensuring a properly functioning driveline. By addressing the changes in suspension geometry and adjusting the pinion angle accordingly, you can maintain optimal driveline performance and avoid potential problems that can arise from incorrect angles.

Significance of Pinion Angle Adjustment: Ensuring Optimal Driveline Performance

Importance of Pinion Angle:

Pinion angle plays a crucial role in the driveline system of lowered trucks. It refers to the angle between the driveshaft and the pinion gear in the differential. When it’s out of alignment, it can cause a cascade of problems, including driveline vibrations and misalignment.

Consequences of an Incorrect Pinion Angle:

An incorrect pinion angle can lead to severe driveline issues. It can cause vibrations that resonate through the entire vehicle, creating an uncomfortable and damaging experience. Furthermore, misalignment can lead to premature wear and tear on driveline components, reducing their lifespan and increasing the risk of failure.

Maintaining Driveline Harmony:

Adjusting the pinion angle is essential for maintaining proper driveline alignment. It ensures that the driveshaft rotates smoothly, without excessive stress or vibration. This harmony is crucial for optimal performance, preventing premature wear and costly repairs.

Related Concepts:

- Driveline vibrations: Excessive vibrations caused by out-of-alignment driveshafts and pinion gear.

- Driveline misalignment: When the driveshaft is not properly aligned with the pinion gear, causing binding and wear.

- Driveline maintenance: Regular inspection and adjustment of pinion angle to maintain optimal performance and longevity.

Methods for Adjusting Pinion Angle

Customizing your lowered truck can bring about exciting transformations, but it’s crucial to pay attention to specific details like pinion angle to ensure a smooth and trouble-free ride. Pinion angle is the angle between the driveshaft and the differential, and getting it right is essential for driveline alignment and optimal performance.

Shims and Control Arms: The Adjustment Tools

A common method for adjusting pinion angle involves the use of shims. These thin metal spacers are placed between the differential and the axle housing, allowing you to fine-tune the angle by varying the shim thickness. For instance, installing shims on the front of the differential will tilt it upward, while placing them at the back will tilt it downward.

Adjustable control arms offer another approach to precise pinion angle adjustments. These control arms allow you to modify the length of the suspension links, thereby altering the driveshaft angle. By adjusting either the upper or lower control arms, you can achieve the desired pinion angle for your lowered truck.

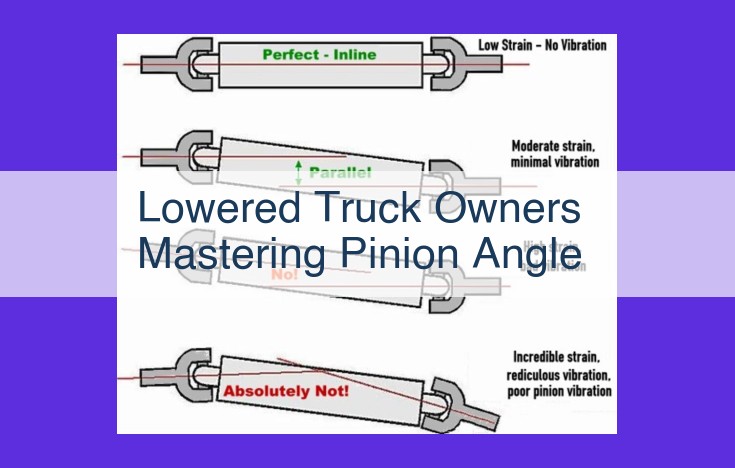

Understanding the Impact of Adjustments

Adjusting the pinion angle using shims or control arms affects the driveshaft angle, which in turn influences the driveline vibrations. The goal is to minimize these vibrations by ensuring the driveshaft spins in a straight line relative to the differential and transmission. When the driveshaft is out of alignment, it can cause a noticeable vibration or “shudder” during acceleration or deceleration.

By understanding the interplay between pinion angle, driveshaft angle, and vibration, you can fine-tune your truck’s suspension to achieve a smooth and enjoyable driving experience.

Measuring Pinion Angle: A Crucial Step for Lowered Trucks

Importance of Accurate Pinion Angle Measurement

When you lower a truck, it’s essential to adjust the pinion angle to maintain proper driveline alignment and prevent costly issues. Pinion angle, the angle at which the driveshaft meets the differential, plays a crucial role in the balance and functionality of your truck.

The Pinion Angle Finder

To measure pinion angle accurately, you’ll need a pinion angle finder, a specialized tool that measures the angle between the driveshaft and the differential yoke. Place the tool securely on the driveshaft and differential yoke, and make sure the frame of the tool is parallel to the ground.

Understanding the Measurement

The pinion angle finder will display the angle in degrees. Positive pinion angles indicate that the driveshaft is pointing upward, while negative pinion angles indicate that it’s pointing downward. The ideal pinion angle for lowered trucks varies depending on the original specifications and driveline geometry.

Consequences of Incorrect Measurement

If the pinion angle is not measured and adjusted correctly, it can lead to serious problems, including:

- Excessive driveline vibrations

- Misalignment of driveline components

- Premature wear on driveline parts

- Reduced fuel efficiency

Benefits of Proper Measurement

Conversely, maintaining a proper pinion angle brings several benefits, such as:

- Improved handling

- Reduced driveline noise

- Extended driveline life

- Smoother and more comfortable ride

Determining the Ideal Pinion Angle for Lowered Trucks

When you lower a truck, it’s crucial to adjust the pinion angle to compensate for the changed suspension geometry. The pinion angle refers to the angle between the driveshaft and the differential input yoke. An incorrect pinion angle can lead to driveline vibrations, misalignment, and premature wear of components.

Factors Affecting Pinion Angle

The original pinion angle specified by the manufacturer is designed to optimize performance for the truck’s original ride height. Lowering the truck alters suspension angles, which in turn affects the pinion angle.

To determine the ideal pinion angle for your lowered truck, it’s essential to consider:

- Original Pinion Angle: Refer to the manufacturer’s specifications or consult a suspension expert.

- Driveline Geometry: Measure the angle of the driveshaft and differential input yoke using a pinion angle finder.

Adjusting Pinion Angle

Once you know the ideal pinion angle, you can adjust it using shims or adjustable control arms. Shims are placed between the differential and the axle housing to change the pinion angle. Adjustable control arms allow for precise adjustments and are recommended for trucks with significant ride height modifications.

Calculating the Ideal Pinion Angle

The ideal pinion angle for a lowered truck varies depending on the specific suspension setup. However, a general rule of thumb is to set the pinion angle:

- Within 1-2 degrees of the original angle

- ** légèrement inférieur à l’angle de fonctionnement du cardan**

For example, if the original pinion angle was 3 degrees and the driveshaft angle is 4 degrees, the ideal pinion angle would be around 2-3 degrees.

By maintaining the correct pinion angle, you can ensure optimal driveline performance, reduce vibrations, extend component life, and improve the overall handling and driving experience of your lowered truck.

**Consequences of Incorrect Pinion Angle**

Driveline Noise and Vibration

An incorrect pinion angle can lead to excessive noise and vibration in the driveline. When the pinion angle is off, the driveshaft will not be rotating smoothly, causing it to vibrate. This vibration can be felt throughout the vehicle, creating an uncomfortable ride for passengers.

Premature Driveline Wear

An incorrect pinion angle can also accelerate wear on the driveline components. The constant vibration from an off-angle pinion can cause damage to the driveshaft, differential, and other driveline parts. This can lead to costly repairs and reduced driveline lifespan.

Reduced Fuel Efficiency

Incorrect pinion angle can also affect fuel efficiency. When the pinion angle is off, the driveshaft is not operating at its optimal efficiency. This can result in increased fuel consumption and reduced gas mileage.

Driveline Misalignment

An incorrect pinion angle can also cause the driveline to become misaligned. This can lead to a number of problems, including:

- Vibrations and noise

- Difficulty shifting gears

- Damage to the driveshaft or differential

Importance of Correct Pinion Angle

It is crucial to maintain the correct pinion angle to ensure a smooth-running and long-lasting driveline. By ensuring the pinion angle is set to the manufacturer’s specifications, you can minimize noise, vibration, wear, and misalignment issues. This will result in a more comfortable and efficient driving experience.

Benefits of a Properly Adjusted Pinion Angle for Lowered Trucks

A well-adjusted pinion angle is crucial for maintaining the health and performance of your lowered truck. Here’s why:

Enhanced Handling

When the pinion angle is set correctly, your driveshaft and differential are in perfect harmony, allowing for smooth power transfer. This translates into improved handling, as the precise alignment ensures that the vehicle responds predictably and effectively to steering inputs.

Reduced Driveline Noise

A misaligned pinion angle can lead to excessive noise and vibration within the driveline. Proper adjustment eliminates these pesky sounds, providing a quieter and more comfortable driving experience.

Extended Driveline Life

A properly aligned driveline reduces wear and tear on its components, including the driveshaft, differential, and wheel bearings. This extends the lifespan of your truck’s driveline, saving you money on costly repairs down the road.

In summary, a proper pinion angle adjustment is essential for your lowered truck. It enhances handling, reduces noise, and prolongs the life of your driveline. Don’t overlook this crucial maintenance step to ensure a smooth and trouble-free driving experience.

Debunking Misconceptions About Pinion Angle

When it comes to modifying lifted trucks, one essential element to consider is pinion angle. Ensuring the correct pinion angle is crucial for maintaining optimal driveline performance, but there are some common misconceptions that can lead to issues.

Myth 1: Pinion Angle is Unaffected by Lowering

This is a prevalent misconception, but it’s essential to understand that lowering a truck directly impacts the pinion angle. When you lower the truck, the driveshaft angle changes, resulting in an incorrect pinion angle. This misalignment can lead to premature wear, vibrations, and reduced performance.

Myth 2: Pinion Angle Adjustment is Complex

Contrary to popular belief, adjusting pinion angle is not an inherently difficult task. With the proper tools and techniques, you can make these adjustments yourself. Understanding the concepts, using the correct shims, and having the right tools can ensure precise alignment.

Reality Check:

Pinion angle is a crucial factor that can significantly impact the driveline’s performance and longevity. By understanding the effects of lowering on pinion angle and the importance of proper pinion angle adjustment, truck enthusiasts can confidently modify their trucks while ensuring optimum performance and reducing potential issues.