Comprehensive Guide To Fuel Injector Programming For Enhanced Efi Engine Performance

- Introduction: Understanding Electronic Fuel Injection (EFI)

- Define EFI and explain its advantages over carburetor systems.

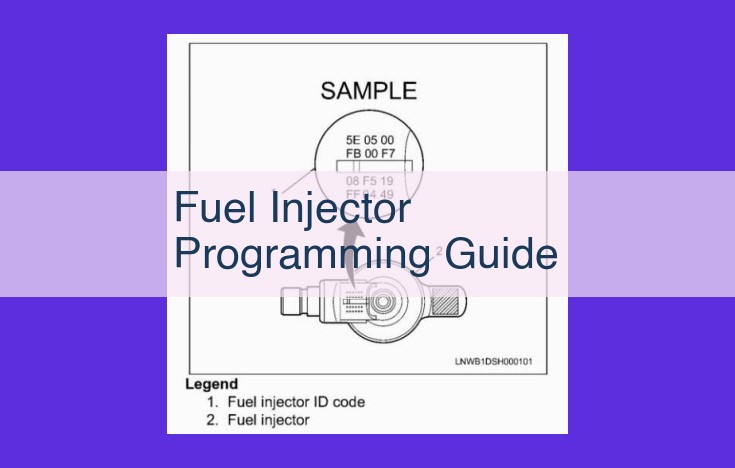

A fuel injector programming guide provides comprehensive information on the principles, components, and techniques involved in programming fuel injectors in electronic fuel injection (EFI) systems. It covers the fundamentals of EFI, the operation of fuel injectors, the importance and factors involved in injector programming, flow rate and lag time calibration, spray pattern optimization, drive and feedback circuits, and the benefits of optimized injector programming for improved engine performance and efficiency.

Electronic Fuel Injection (EFI): Revolutionizing Engine Performance

In the realm of automotive engineering, the advent of Electronic Fuel Injection (EFI) has transformed the way engines operate, delivering a myriad of benefits over traditional carburetor systems. EFI employs sophisticated technology to precisely control the delivery of fuel into the engine’s cylinders, optimizing performance, fuel efficiency, and emissions.

Unlike carburetors, which rely on atmospheric pressure to draw fuel through a venturi, EFI utilizes fuel injectors to spray atomized fuel directly into the intake manifold or combustion chamber. This precise injection ensures an optimal air-fuel mixture for each combustion cycle, resulting in improved engine response, power, and torque.

Furthermore, EFI allows for real-time adjustment of fuel delivery based on engine operating conditions. Sensors throughout the engine monitor parameters such as air flow, temperature, and throttle position, providing the Engine Control Unit (ECU) with critical data. The ECU then adjusts the injector pulse width and timing to deliver the exact amount of fuel required for optimal combustion.

By eliminating the limitations of carburetors, EFI enhances engine performance in several ways:

- Improved fuel efficiency: Precise fuel metering reduces fuel waste and optimizes combustion, leading to better fuel economy.

- Increased power and torque: Optimized air-fuel mixtures enhance engine power and torque, providing improved acceleration and responsiveness.

- Reduced emissions: Precise fuel control minimizes the production of harmful pollutants, such as carbon monoxide, hydrocarbons, and nitrogen oxides.

- Smoother engine operation: EFI eliminates engine hesitation and improves idle stability, resulting in a more refined and enjoyable driving experience.

The Heart of EFI: Fuel Injectors

In the intricate symphony of an internal combustion engine, the fuel injector stands as the precision conductor, delivering the lifeblood that fuels the machine. Unlike the humble carburetor of yesteryear, this technological marvel orchestrates the strategic injection of fuel directly into the heart of the engine. It is the beating heart of Electronic Fuel Injection (EFI), a system that has revolutionized engine performance and efficiency.

Fuel injectors are electromechanical devices that atomize and spray fuel into the engine’s combustion chamber at precisely controlled timing and quantity. They operate under the watchful eye of the Engine Control Unit (ECU), which carefully orchestrates their operation based on sensor feedback. Unlike carburetors, which rely on the venturi effect to passively draw fuel into the intake manifold, fuel injectors actively control the fuel flow, ensuring optimal air-fuel ratios for each combustion event.

The fuel injector itself is a precision-engineered marvel. It consists of a solenoid valve that controls the opening and closing of a tiny nozzle. When voltage is applied to the solenoid, it opens the valve, allowing high-pressure fuel from the fuel rail to flow through the nozzle. This fuel is then atomized, creating a fine mist that can be easily mixed with air and ignited to create combustion.

Fuel injectors play a crucial role in ensuring optimal engine performance. By precisely controlling the timing and quantity of fuel injected, they can optimize fuel efficiency, reduce emissions, and enhance engine power. Advanced fuel injection systems even use multiple injectors per cylinder to create a more homogeneous air-fuel mixture and improve combustion efficiency.

In summary, fuel injectors are the heart of EFI systems. They are responsible for delivering the precise amount of fuel at the exact right time, enabling engines to operate at peak efficiency, power, and cleanliness. As the demand for efficient and environmentally friendly transportation continues to grow, fuel injection technology will undoubtedly continue to evolve and innovate.

Fuel Injector Programming: Calibrating Injection for Optimal Engine Performance

Electronic fuel injection (EFI) systems rely heavily on precisely calibrated fuel injectors to deliver the right amount of fuel, at the right time, and in the correct spray pattern. Fuel injector programming is critical to ensure that the engine runs efficiently, smoothly, and cleanly.

Importance of Injector Programming

Improperly programmed fuel injectors can result in a range of issues, including:

- Poor fuel efficiency

- Loss of power

- Increased emissions

- Engine damage

Key factors in injector programming include:

- Fuel pressure: The pressure at which fuel is supplied to the injectors.

- Injector pulse width: The duration of time that the injector remains open, determining the amount of fuel delivered.

- Injector timing: The point in the engine cycle when the injector opens and closes, ensuring optimal combustion.

Customizing Injection to Engine Needs

Fuel injector calibration is a process of tailoring the injector’s performance to the specific requirements of the engine. This involves adjusting the flow rate and lag time of the injectors.

Flow Rate

Flow rate refers to the quantity of fuel delivered by the injector per unit time. It is measured in cubic centimeters per minute (cc/min). Calibrating the flow rate ensures that the engine receives the correct amount of fuel for its operating conditions.

Lag Time

Lag time is the delay between the moment the injector receives an electrical signal and when it begins to deliver fuel. It is measured in milliseconds (ms). Calibrating lag time ensures that the fuel is injected at the precise moment required for optimal combustion.

Optimizing Performance

Properly programmed and calibrated fuel injectors contribute to:

- Improved fuel efficiency by precisely delivering the necessary amount of fuel.

- Increased power by ensuring optimal combustion and throttle response.

- Reduced emissions by minimizing unburned fuel and optimizing air-fuel ratio.

- Enhanced engine operation by eliminating hesitation, stalling, and surging.

In summary, fuel injector programming is essential for calibrating fuel injection to match the unique requirements of an engine. By adjusting flow rate and lag time, injectors can be optimized to deliver the right amount of fuel, at the right time, and in the correct spray pattern, resulting in peak engine performance, efficiency, and reliability.

Fuel Injector Calibration: Tailoring to Engine Needs

Understanding the intricacies of Electronic Fuel Injection (EFI) systems is crucial for maximizing engine performance. At the heart of EFI lies the fuel injector, responsible for delivering precise amounts of fuel into the engine’s combustion chambers. Proper calibration of these injectors ensures optimal engine operation, enhancing fuel efficiency, power output, emissions control, and overall drivability.

Fuel injector calibration involves two key parameters: flow rate and lag time. Flow rate determines the volume of fuel delivered by the injector per unit time. Adjusting the flow rate caters to specific engine requirements, such as displacement, compression ratio, and power output. By fine-tuning the flow rate, the engine can receive the precise amount of fuel it needs to operate efficiently and deliver optimal performance.

Lag time, on the other hand, refers to the delay between the moment the injector receives an electrical signal and the actual fuel delivery. Calibrating lag time is critical for ensuring accurate ignition timing and optimal combustion. Proper timing allows the air-fuel mixture to reach optimal conditions at the time of spark ignition, resulting in efficient fuel burn and reduced emissions.

Through meticulous calibration, fuel injectors are customized to meet the unique demands of each engine. This process ensures that the engine receives the correct fuel quantity and timing, leading to improved engine response, reduced fuel consumption, and enhanced emissions control. By understanding the significance of fuel injector calibration, engine tuners and enthusiasts can optimize engine performance, unlocking its full potential.

Fuel Injector Flow Rate: Delivering Precise Amounts

At the heart of Electronic Fuel Injection (EFI) systems lies the crucial task of delivering the right amount of fuel at the right time. This is where fuel injectors come into play, and one of their key characteristics is their flow rate.

Fuel injector flow rate refers to the volume of fuel that an injector can deliver per unit of time, typically measured in cubic centimeters per minute (cc/min). It’s a crucial parameter that directly impacts the amount of fuel delivered to the engine’s cylinders.

Precise Flow Rate Control

In an EFI system, the fuel injector flow rate is meticulously controlled by the Engine Control Unit (ECU). The ECU uses various sensors to monitor engine conditions, such as air flow, throttle position, and engine speed. Based on this data, it calculates the optimal amount of fuel required and adjusts the injector flow rate accordingly.

Matching Engine Needs

The fuel injector flow rate is not a static value but must adapt to changing engine needs. For instance, during acceleration, the engine requires more fuel, triggering the ECU to increase the injector flow rate. Conversely, during deceleration, less fuel is required, leading to a reduced flow rate.

Optimizing Performance

By precisely controlling the fuel injector flow rate, EFI systems ensure that the engine receives the precise amount of fuel needed for optimal performance. This translates into improved fuel efficiency, as excess fuel is avoided. It also enhances power output by ensuring that the engine has sufficient fuel to meet high-power demands.

Reduced Emissions

Accurate flow rate control also contributes to lowering emissions. By delivering the correct amount of fuel, EFI systems minimize unburnt fuel, which can otherwise contribute to tailpipe emissions. This helps vehicles meet stringent emission standards and reduce their environmental impact.

Fuel Injector Lag Time: Ensuring Optimal Timing

In the symphony of an engine’s performance, timing is everything. Just as a conductor orchestrates the precise interplay of instruments, the engine’s Electronic Control Unit (ECU) orchestrates the injection of fuel. Fuel injector lag time, a critical factor in this process, ensures that the fuel arrives at the combustion chamber at the optimal moment, maximizing efficiency and power.

Imagine a race car driver. As they approach a corner, they must anticipate the timing of the turn and adjust their speed accordingly. Similarly, the ECU calculates the exact timing of fuel injection based on engine parameters such as speed, load, and temperature. This timing ensures that the fuel is present in the cylinder when the spark plug ignites, creating the perfect combustion event.

However, there’s a slight delay between the ECU’s command and the injector’s actual opening. This delay, known as fuel injector lag time, is caused by the physical properties of the injector. When the ECU sends a signal, the injector’s solenoid valve opens, allowing fuel to flow through it. But this opening process takes a fraction of a second, and the fuel then needs to travel through the injector’s nozzle and into the combustion chamber.

Lag time is crucial because it affects the timing of the combustion event. If the lag time is too long, the fuel will arrive in the cylinder after the spark has ignited, resulting in inefficient combustion and wasted fuel. Conversely, if the lag time is too short, the fuel will arrive too early, potentially causing detonation or knocking.

To minimize lag time, fuel injector manufacturers employ various design techniques. These include optimizing the solenoid valve’s response time and reducing the distance the fuel must travel within the injector. By fine-tuning these parameters, they ensure that the injector opens and delivers fuel at precisely the right moment.

Through careful engineering, fuel injector lag time is controlled to a minimum. This allows the engine to operate at its optimal efficiency, delivering power when needed while minimizing emissions and fuel consumption. So, when you’re behind the wheel, remember that even the tiniest of delays, like fuel injector lag time, play a vital role in the performance and smoothness of your driving experience.

Fuel Injector Spray Pattern: Shaping the Fuel Mist

In the world of electronic fuel injection, the fuel injector reigns supreme. But beyond the intricacies of flow rates and lag times, there’s an often-overlooked aspect that plays a crucial role in combustion efficiency: the spray pattern.

The spray pattern refers to the way fuel is distributed when it exits the injector. It directly influences how evenly the fuel mixes with air, creating a more uniform and efficient combustion process.

A well-defined spray pattern ensures that fuel droplets are evenly distributed within the combustion chamber. This optimizes fuel-air mixing, resulting in more complete combustion. In contrast, a poorly defined pattern can lead to fuel droplets clumping together, which can create localized rich and lean areas within the cylinder. This can compromise combustion efficiency and increase emissions.

The shape of the spray pattern is determined by several factors, including the injector nozzle design and the fuel pressure. Engineers carefully optimize these parameters to create a spray pattern that complements the engine’s combustion chamber design.

For instance, direct injection engines, where fuel is injected directly into the cylinder, often use narrow spray patterns to minimize fuel impingement on the cylinder walls. This helps prevent unburned fuel from escaping the combustion process.

On the other hand, port fuel injection engines, where fuel is injected into the intake port, typically employ wider spray patterns to ensure thorough mixing with the incoming air.

The impact of spray pattern extends beyond combustion efficiency. It also influences engine emissions and drivability. A well-optimized spray pattern can reduce particulate and hydrocarbon emissions by ensuring complete combustion. Additionally, it can improve throttle response and overall engine smoothness by minimizing fuel droplet bounce-off effects.

In conclusion, the fuel injector spray pattern plays a crucial role in the performance and efficiency of modern engines. By understanding the factors that influence spray pattern formation, engineers can optimize fuel injector design to maximize combustion efficiency, reduce emissions, and improve drivability.

Fuel Injector Drive Circuit: The Lifeline of Fuel Injection

In the realm of Electronic Fuel Injection (EFI), the fuel injector drive circuit stands as the unsung hero, playing a crucial role in powering the fuel injectors and ensuring their flawless operation. This intricate electrical pathway serves as the lifeline, delivering the necessary electrical current to these vital components.

Imagine a fuel injector as a precision instrument, a tiny but powerful valve that precisely controls the flow of fuel into the engine. To perform their delicate task, these injectors rely on a constant supply of electrical energy. The fuel injector drive circuit fulfills this essential need, providing a steady stream of current to energize the injector’s solenoid, which in turn opens and closes the valve.

The drive circuit is a meticulously engineered masterpiece, designed to withstand the harsh conditions of the engine compartment. It must function flawlessly under extreme temperatures, vibrations, and electrical interference. The circuit employs high-quality components, carefully selected for their durability and resistance to environmental stressors.

The design of the drive circuit considers the electrical characteristics of the fuel injectors. Each injector has a specific resistance and inductance, which the circuit must accommodate to deliver the optimal amount of current. This delicate balance ensures that the injector opens and closes at precise intervals, enabling the engine to receive the precise fuel it needs at the right time.

Moreover, the drive circuit often incorporates sophisticated protection features to safeguard both the injectors and the engine. These features can detect and prevent over-current conditions, which could damage the injectors or lead to engine damage. By constantly monitoring the electrical parameters of the injectors, the drive circuit acts as a vigilant guardian, preventing potential issues before they arise.

In summary, the fuel injector drive circuit is a critical component of EFI systems, providing the electrical power that drives the fuel injectors. Its flawless operation ensures that the engine receives the precise amount of fuel it needs, leading to optimal performance, fuel efficiency, and emissions control. Without this essential circuit, EFI systems would be unable to function, and the modern combustion engine would lose its refined and efficient character.

Fuel Injector Feedback Circuit: Monitoring and Adjustment

- Describe how the feedback circuit monitors injector operation and provides feedback to the ECU.

Fuel Injector Feedback Circuit: Monitoring and Adjustment

Electronic Fuel Injection (EFI) systems utilize a sophisticated feedback circuit to monitor the operation of fuel injectors and provide real-time adjustments to ensure optimal fuel delivery. This closed-loop system plays a crucial role in maintaining engine efficiency, reducing emissions, and maximizing performance.

The feedback circuit is engineered with sensors that constantly monitor key parameters of the injector’s operation, such as resistance and current draw. These sensors relay the data to the Engine Control Unit (ECU), the central brain of the EFI system. The ECU analyzes the data to determine if the injector is functioning properly and delivering the correct amount of fuel.

Should any discrepancies arise, such as a clogged or faulty injector, the ECU swiftly initiates corrective measures. It adjusts the injector’s pulse width, modifying the duration of the electrical signal that triggers the injector’s opening and closing. By finely tuning the pulse width, the ECU ensures that the injector delivers the precise amount of fuel needed for optimal combustion.

The feedback circuit not only monitors injector operation but also provides valuable data to the ECU for adaptive learning and optimization. The ECU uses the feedback information to identify any deviations in injector performance over time and compensates for those changes by adjusting the programming accordingly. This constant monitoring and fine-tuning ensure that the fuel injection system remains highly efficient and adapts to changing engine conditions.

In summary, the fuel injector feedback circuit is an integral part of the EFI system that continuously monitors injector operation, provides feedback to the ECU, and allows for real-time adjustments. By ensuring optimal fuel delivery, it maximizes engine performance, minimizes emissions, and enhances overall driving experience.

Optimizing Fuel Injector Programming: Unlocking Enhanced Engine Performance

Optimizing fuel injector programming is a crucial step in ensuring the optimal performance of your vehicle’s engine. By fine-tuning the injector parameters, you can achieve significant improvements in fuel efficiency, power output, emissions, and overall engine operation.

Enhanced Fuel Efficiency

Precise fuel injector programming allows for more precise fuel delivery, eliminating wastage and ensuring that only the necessary amount of fuel is injected into the combustion chamber. This efficiency translates into more miles per gallon, saving you money at the pump.

Increased Power and Responsiveness

Optimized injector programming enables the engine to receive the exact amount of fuel required for optimal combustion. This results in a more powerful and responsive engine, especially noticeable during acceleration and high-load situations.

Reduced Emissions

By ensuring proper fuel-to-air ratios, optimized injector programming minimizes the production of harmful emissions. This contributes to cleaner air quality and reduced environmental impact.

Improved Engine Operation

Properly programmed fuel injectors ensure consistent fuel delivery, eliminating engine hesitation and rough idling. It also reduces wear and tear on engine components, extending its lifespan.

Fine-tuning for Specific Applications

The benefits of injector programming optimization extend to specific vehicle applications. Whether it’s a performance car, a heavy-duty truck, or a fuel-efficient hybrid, optimizing injector programming can enhance its unique performance characteristics.

In conclusion, optimizing fuel injector programming is an essential step for maximizing the efficiency, power, emissions, and overall performance of your engine. By investing time and effort in fine-tuning these parameters, you can unlock the full potential of your vehicle and enjoy a more satisfying driving experience.