Craft Authentic Roman Centurion Helmets: A Comprehensive Guide To Historical Accuracy

Discover the art of crafting authentic Roman centurion helmets in this comprehensive guide. Learn about the historical significance of these iconic helmets and the materials and tools needed for their accurate construction. Master techniques for woodworking, metalworking, and casting to create functional and aesthetically pleasing replicas. Enhance your helmet with finishing touches like painting and varnishing, ensuring its beauty and protection. Prioritize safety throughout the crafting process and strive for historical accuracy to create a helmet that is both a functional piece of art and an educational tool.

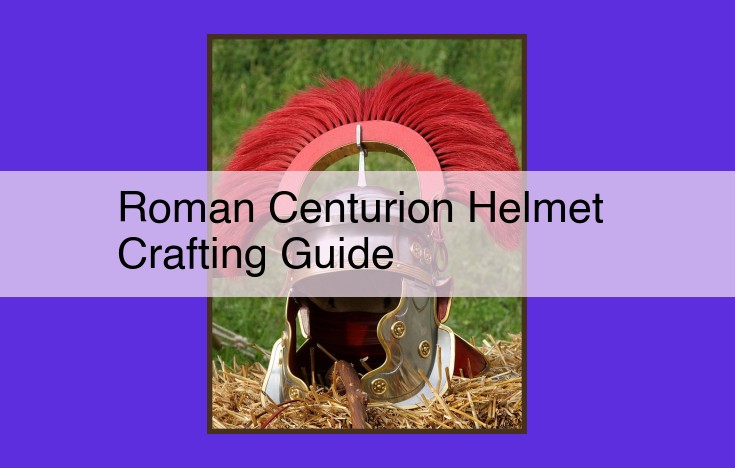

The Alluring Enchantment of Authentic Roman Centurion Helmets

Throughout the annals of history, the image of a Roman centurion donning an ornate helmet has captivated our imaginations. These iconic helmets not only served as protective gear but also symbolized the strength, valor, and authority of the Roman Empire. In this guide, we embark on a journey to explore the intricate art of crafting authentic Roman centurion helmets, preserving the legacy of these legendary warriors.

Historical Significance and Timeless Appeal

Roman centurion helmets, with their distinctive crests and elaborate decorations, played a crucial role in the Roman military. They protected the wearer’s head from enemy blows while simultaneously projecting an aura of authority and command. Beyond the battlefield, these helmets became symbols of Roman power and prestige, immortalized in countless works of art and literature.

Unveiling the Secrets of Authentic Crafting

Crafting an authentic Roman centurion helmet requires a deep understanding of the materials and techniques employed by ancient Roman artisans. From the finest hardwoods to resilient metals and supple fabrics, each component is meticulously chosen to replicate the original designs. By mastering woodworking, metalworking, and fabric manipulation, artisans can breathe life into these historical artifacts.

Precision and Efficiency: The Right Tools for the Job

To achieve historical accuracy, it is essential to utilize the appropriate tools. Hand tools like hammers, chisels, and saws allow for intricate shaping and detailing. Power tools such as drills and sanders enhance efficiency, while machinery like lathes and milling machines provide precision and versatility. The right tools empower artisans to execute complex techniques with surgical accuracy.

Masterful Techniques for Functional and Aesthetic Appeal

The construction of a Roman centurion helmet involves a delicate balance of structural integrity and aesthetic beauty. Carpentry and joinery techniques ensure a solid and durable foundation. Welding and forging strengthen metal components, enhancing their resistance to battle damage. Casting and molding techniques bring intricate embellishments to life, evoking the splendor and opulence of ancient Rome.

Finishing Touches: Enhancing Beauty and Protection

Once the helmet has been crafted, it undergoes meticulous finishing processes to achieve its final form. Sanding smooths rough surfaces, preparing them for paint or staining. Painting and staining provide color and protective layers, ensuring the helmet stands the test of time. Varnishing and polishing enhance the helmet’s luster, protecting it from wear and tear while accentuating its stunning details.

Prioritizing Safety: A Smooth and Risk-Free Crafting Process

Safety is paramount throughout the crafting process. A well-organized workspace with ample lighting and ventilation minimizes risks. Regular tool maintenance ensures sharp and safe tools. Protective equipment like gloves, goggles, and respirators protects artisans from potential hazards, enabling them to work with confidence.

Achieving Historical Accuracy: Education Through Authenticity

Historical accuracy is the guiding principle behind every step of the crafting process. By using period-specific materials, employing authentic techniques, and meticulously recreating details, artisans produce helmets that are not only beautiful but also educative. Each helmet becomes a living testament to the ingenuity and craftsmanship of ancient Roman armorers.

Materials for Historical Authenticity

When embarking on the noble task of crafting an authentic Roman centurion helmet, the choice of materials is paramount.

Woodworking:

The foundation of a centurion’s helmet lies in its wooden frame. Oak, cherry, and ash were the woods of choice for their strength, durability, and workability. Ancient craftsmen used form-making techniques to shape the wood into the helmet’s iconic curved form.

Metalworking:

Reinforcing this wooden framework was the responsibility of metal. Bronze, iron, and steel were commonly employed for their hardiness and ability to withstand the rigors of battle. Reinforcement techniques such as welding and forging ensured the helmet’s structural integrity, while intricate embellishments added an air of martial elegance.

Fabric:

For comfort and protection, the helmet’s interior was lined with fabric. Leather, linen, and wool were favored for their breathability, cushioning, and durability, ensuring that even under the scorching sun or relentless rain, the wearer remained relatively at ease. Cheek pieces, attached to the helmet’s sides, were also crafted from these fabrics, providing additional support and protection.

By meticulously selecting and working with these authentic materials, you embark not only on a crafting journey but also on a historical pilgrimage, honoring the artisans and warriors who once donned these iconic helmets.

Essential Tools for Precision and Efficiency

In the pursuit of crafting authentic Roman centurion helmets, the right tools are indispensable. These essential instruments facilitate precision, efficiency, and the realization of meticulous historical accuracy.

Hand Tools: The Foundation of Craftsmanship

Hand tools form the cornerstone of the helmet-making process. Hammers of various shapes and sizes provide the force for shaping metal and wood. Chisels and saws allow for intricate carving and cutting, creating precise forms and detailing. Each tool serves a specific purpose, demanding skillful handling and precise technique.

Power Tools: Modern Alchemy for Efficiency

Power tools enhance the craftsman’s capabilities, enabling greater efficiency and accuracy. Drills power through tough materials, while sanders smooth out surfaces, preparing them for further processing. These tools accelerate the crafting process, allowing for the creation of helmets with exceptional precision and detail.

Machinery: Industrial Precision for Complex Creations

Machinery represents the pinnacle of helmet-making technology. Lathes spin metal or wood, allowing for precise turning and shaping. Milling machines create intricate contours and engravings, adding authentic detail and functional reinforcement to the helmet’s structure. These machines enable the creation of complex forms and designs that would be impossible by hand alone.

The tools described above form an essential arsenal for the meticulous crafting of authentic Roman centurion helmets. By understanding their specific functions and applications, craftsmen can harness their power to achieve the highest levels of precision and efficiency, ultimately producing helmets that are both historically accurate and aesthetically captivating.

Mastering Techniques for Functional and Aesthetic Appeal

- Carpentry and Joinery: Constructing the helmet’s form, joinery methods, and their impact on durability.

- Welding and Forging: Reinforcing metal components, shaping techniques, and enhancing strength.

- Casting and Molding: Creating intricate embellishments, casting techniques, and materials used.

Mastering Techniques for Functional and Aesthetic Appeal

In the realm of crafting authentic Roman centurion helmets, the mastery of techniques plays a pivotal role in achieving both functional and aesthetic perfection. From the intricate woodwork to the gleaming metal embellishments, every aspect of the helmet’s construction is a testament to the craftsman’s skill and dedication.

Carpentry and Joinery: The Foundation of the Helmet’s Form

The helmet’s rugged form is meticulously crafted using time-honored carpentry techniques. The choice of wood is crucial, with hardwoods like oak and walnut providing the necessary strength and durability. Joiners employ precise joinery methods to assemble the components, ensuring impregnable construction that can withstand the rigors of battle.

Welding and Forging: Reinforcing and Shaping the Metal

Metalworking plays a vital role in reinforcing the helmet’s vulnerable areas and enhancing its overall strength. Expert welders skillfully fuse metal components, while blacksmiths forge intricate embellishments that add both beauty and structural integrity. The use of high-quality metals ensures that the helmet can deflect blows and withstand the harsh conditions of combat.

Casting and Molding: Creating Intricate Embellishments

The cast and molded embellishments that adorn Roman centurion helmets are a testament to the craftsman’s artistic prowess. Using ancient casting techniques, molten metal is poured into intricate molds to create lifelike depictions of mythical creatures, military symbols, and Roman eagles. These embellishments not only enhance the helmet’s aesthetic appeal but also provide symbolic protection for the wearer.

Finishing Touches for Beauty and Protection

The final stages of crafting a Roman centurion helmet involve meticulous attention to detail, ensuring both its aesthetic appeal and durability. These finishing touches enhance the helmet’s beauty while protecting it from the elements and wear and tear.

Sanding: Smoothing Surfaces and Preparing for Paint

Sanding is crucial for creating a smooth surface, removing any imperfections or rough edges. Different grades of sandpaper are used, starting with a coarse grit to eliminate blemishes and transitioning to finer grits for a polished finish. This process ensures the paint adheres evenly and provides a smooth base for the intricate designs and embellishments to come.

Painting and Staining: Authentic Color Schemes and Protection

The color of the Roman centurion helmet varied depending on the era and ranking. Painting and staining are employed to achieve the desired color scheme, using historically accurate pigments and techniques. Multiple coats of paint provide a protective layer against moisture and weathering, preserving the vibrant hues and intricate details over time.

Varnishing and Polishing: Enhancing Luster and Durability

Varnishing and polishing are the final touches that enhance the helmet’s appearance and durability. Varnish adds a protective layer that protects the paint from fading and scratches, providing a glossy or matte finish depending on the desired effect. Polishing brings out the natural luster of the helmet, making it a visually striking and unique masterpiece.

Prioritizing Safety for a Smooth Crafting Process

When embarking on the immersive journey of crafting an authentic Roman centurion helmet, safety should be your steadfast companion, ensuring a seamless and fulfilling experience. By adhering to essential safety measures, you can create an environment conducive to productivity and minimize the risk of accidents.

Workshop Safety: A Clean and Organized Sanctuary

Your workshop, the birthplace of your centurion masterpiece, must be a sanctuary of cleanliness and organization. Ensure ample lighting illuminates your workspace, allowing you to navigate safely and perform intricate tasks with precision. Keep your tools organized, each having its designated place, preventing clutter and the potential for accidents.

Tool Maintenance: Sharpened and Pristine

Your tools are the instruments of your creativity, but they must be maintained with the utmost care. Regularly sharpen your chisels, saws, and other cutting tools to ensure their sharpness and prevent them from becoming blunt and hazardous. Proper maintenance not only enhances their performance but also reduces the risk of dangerous accidents.

Protective Equipment: Your Shield Against Hazards

Protective equipment is your armor against potential dangers lurking in the workshop. Gloves safeguard your hands from splinters, cuts, and burns. Goggles shield your eyes from flying debris and harmful fumes. Respirators protect your lungs from inhaling harmful dust and particulates. By donning this protective gear, you minimize the risk of injuries and safeguard your health for the long haul.

Achieving Historical Accuracy for Authenticity and Education

Using Period-Specific Materials

Authenticity demands the use of materials consistent with the era of Roman centurions. This means sourcing wood, metals, and fabrics that were readily available and utilized during that time. Careful research into historical documents and archaeological evidence will guide the selection of these materials, ensuring the creation of a helmet that is both faithful to history and visually stunning.

Employing Authentic Techniques and Tools

Beyond materials, the techniques and tools employed in crafting the helmet must also adhere to historical accuracy. The skilled artisans of ancient Rome used a variety of woodworking, metalworking, and molding techniques to create these iconic helmets. Modern craftsmen must master these same techniques, whether by hand or with the aid of modern machinery, to produce a helmet that is not only functional but also authentic.

Meticulous Attention to Detail

The essence of historical accuracy lies in the meticulous attention to detail. This involves not only replicating the basic form and structure of Roman centurion helmets but also incorporating the intricate designs, embellishments, and details that make each helmet unique. From the bold crest to the intricate scrollwork, every element must be carefully researched and executed to create a helmet that is a true work of art and a testament to the craftsmanship of the ancient world.